Using LM-80 measurement methodology to determine the true value of packaged LEDs

At Strategies in Light 2015, MONICA HANSEN, LED Lighting Advisors, and LYNN DAVIS, RTI International, will elaborate on a methodology used to assess LM-80 data across a variety of packaged LEDs in an effort to determine the effects of different LED platform designs and materials on performance, light quality metrics, and cost.

Over the past two years, there has been a broad market acceptance of mid-power LEDs used for lighting fixtures, disrupting high-power LEDs as the package for general lighting applications. Due to their low costs and improving efficacy, mid-power LED market value is surpassing that of high-power LEDs. In addition, chip-on-board (COB) arrays are steadily gaining market share in some applications and are expected to increase in market penetration over the next several years. LED component cost is only one factor when considering LED selection; other factors, such as efficacy, color stability, and lumen maintenance weigh in on the true cost of LED choices for lighting systems.

The implications of different LED platform designs and materials of construction — as they relate to performance, color quality, lumen maintenance, and color shift — have been investigated for a variety of LED packages. In performing this analysis, a methodology was developed to analyze LM-80 data across multiple manufacturers to provide new insights into LED-level factors impacting true costs. The data from more than 100 different LED products was analyzed using this methodology and supplemented with new experimental data. Based on this analysis, a detailed look at lumen maintenance and color shift behavior of the main LED component platforms has shown that the materials of construction at the die and package level will impact the performance of the LEDs.

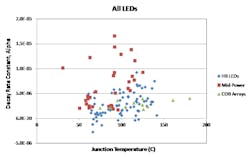

The lumen maintenance of LED products can be evaluated using the LM-80 method combined with TM-21 projections. This process calculates a decay rate constant (a) that provides a measure of the rate of luminous flux change. Higher α values indicate faster lumen depreciation whereas small α values indicate longer lumen maintenance times. Decay rate constants for the more than 100 products were examined in this analysis as shown in the figure. Several trends can be observed in the data including (1) a general increase in α with junction temperature, and (2) a separation of a values by package types. As demonstrated by Koh et al., α values smaller than 1.4×10-5 will meet the current Energy Star requirements. Most of the LEDs examined in this study will meet Energy Star requirements for lumen maintenance provided the junction temperature is properly controlled.

Decay rate constants for more than 100 LED products classified according to package type.

Experimental studies utilizing accelerated life tests (ALT) performed by RTI International have also provided insights into the impact of LED package on lumen maintenance and color point stability. Factors impacting color point stability in LEDs include changes in the phosphor, emitter, and encapsulant with aging. Emitters can have radiant flux decreases and emission wavelength shifts over time; phosphors can experience quantum efficiency decreases or emission spectrum shifts due to oxidation; and encapsulants can exhibit cracking, oxidation, and yellowing or changes in index of refraction.

The impact of the phosphor binder material selection on color shift was identified by RTI in one experiment. Wet high temperature operating life (WHTOL) testing was performed on individual high-brightness LEDs at 85/85 temperature/relative humidity settings. The LED test samples were two different, widely-used LED models that have excellent field performance. Both have a silicone lens but they have different binder materials in the phosphor layer — one with a glass binder and the other with a silicone binder. Three different LED colors from the two different manufacturers were tested: warm white, cool white, and blue.

The results from 4000 hours of 85/85 WHOTL testing indicate the color stability of the blue LEDs from the two manufacturers was roughly the same, showing a negligible wavelength shift over time. There was, however, different behavior observed for warm white LEDs that may be due to binder materials used in construction. A sharp linear rise in Δu’v’ was observed for the warm white LEDs with silicone binder resulting in a color shift of 0.025 after 4000 hours. By comparison, the warm white LEDs with a glass binder exhibited a plateau in Δu’v’ of approximately 0.005.

The color shift seen in the warm white LEDs with the silicone binder is attributed to a significant shift in red/orange emission with the main peak shifting from approximately 610 nm to 580 nm during the 4000 hours. Similar trends are also observed in LM-80 data, although the magnitude of these effects are increased in WHTOL testing compared to normal usage. The warm white LEDs with the glass binder, though, show no substantial shifts of the peak emission. Cool white products also tended to shift much less than warm white products and had comparable performance for both sets of LEDs (silicone and glass binders).

More results on the impact of materials of construction at the package level will be presented at Strategies in Light 2015.

This research has been performed in collaboration with RTI International and is based upon work supported by the Department of Energy under Award Number DE-EE0005124.

Register now for Strategies in Light and the co-located event The LED Show!

MONICA HANSEN is owner and consultant at LED Lighting Advisors (http://ledlightingadvisors.com). LYNN DAVIS is director of engineering research at RTI International (www.rti.org).