Properties of LED light can boost poultry production and profits (MAGAZINE)

The energy-efficient, narrow-band emission of LED sources makes the lighting technology valuable in life science applications. KEN MARRIN examines how solid-state lighting is being deployed in poultry-rearing applications to both reduce electrical expenses and boost production.

The demand for food worldwide is expected to double by 2030. To meet that demand, producers are adopting new technologies that will enable them to increase production at a reduced cost with less stress on the environment. Most of these production technologies focus on enhancing traditional inputs such as water, air, nutrients, and housing. One largely unexplored production input is light.

By utilizing LED lighting and taking advantage of the unique spectral requirements of poultry, swine, dairy cattle, fish, or crustaceans, farmers can reduce stress and mortality, regulate circadian rhythm, and substantially increase the production of eggs, meat, and other protein sources, while dramatically reducing energy use and other input costs.

As noted in a June 2013 LEDs Magazine article, niche applications enabled by solid-state lighting (SSL) include lighting specific to agriculture, and such applications could yield significant revenue potential. Major players in the SSL industry, such as Philips and Osram Sylvania, have developed spectrally-tuned LED lamps for farming and horticulture, in addition to smaller businesses such as Once Innovations, Luma Vue, and NextGen Illumination manufacturing LED lamps exclusively for the poultry market.

Many livestock farmers still utilize general-purpose residential and commercial 60W, 80W, and 100W incandescent lamps in their barns. These lamps are well suited to human environments, but incandescent light is not the same as sunlight, and the best light for humans is not necessarily the best light for animals. Animals have evolved living under the sunlight, whose spectrum differs substantially from that of incandescent light. Sunlight is a combination of all colors. Fig. 1a shows the amount of each color present in typical sunlight at noon. Note that the blues and greens are brighter than the reds at this time of the day. Fig. 1b shows the amount of color present in typical sunlight at the end of the day. Note that the reds are now brighter than the greens and the blues.

Modern barn lighting systems attempt to mimic the sun’s spectrum, which provides a continuous spectrum containing all colors with no gaps in between. Incandescent light (Fig. 2a) effectively simulates sunlight at sunset, producing a continuous spectrum rich in reds with diminished greens and very little blue. However, this spectrum does not simulate midday sunlight, which is rich in blues and greens with diminished red. Some manufacturers try to put coatings on the bulbs to alter the spectrum, but this approach does not produce a continuous spectrum. Incandescent bulbs are also highly inefficient (producing more heat than light), burn out often, and require a fixture that is wet-location rated. All that will soon be moot, of course, as new production of incandescent lights is banned.

Compact fluorescent lamps (CFLs) have good efficiency and produce white light, but again, CFL light output is tailored to human vision. The white light is achieved by producing and combining narrow bands of red, green, and blue. As a result, there are large gaps in the spectrum between the red, blue, and green spikes, and many of the red, blue, and green wavelengths present in sunlight are lost (Fig. 2b). Blue light is exceptionally weak, and most of the deeper reds are lost. Overall, CFLs do a terrible job of mimicking natural sunlight. They are also hard to clean (because of their curly shape), contain small amounts of toxic mercury, require an enclosure to be wet rated, and do not dim well — plus their lifetime is shortened significantly when dimmed.

High-pressure sodium (HPS) bulbs offer excellent efficiency and high light output, with a color spectrum that is strongest in the reds and yellows, thus giving the bulbs their distinctive orange-yellow or amber hue. As with CFLs, however, much of the color spectrum is missing, especially the greens and blues. HPS lamps are also very difficult to dim, are slow to warm up, require a ballast for operation, have high upfront costs, and may contain sodium and/or mercury.

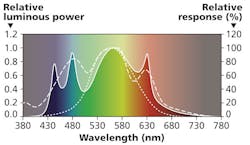

LEDs are the most efficient and environmentally friendly of the agricultural lighting options, producing white light by combining a blue LED with red and green phosphors. The spectrum is near continuous (Fig. 3) with especially strong blues, but also ample green and red. While not exactly daylight, the LED spectrum provides a close approximation of daylight from a human’s point of view, without the spectral gaps of other technologies. They also have the longest lifetime (up to 10 years with 24/7 operation), are highly rugged, are not susceptible to shock or vibration, and allow for color shifting and color control. LEDs have high upfront costs, but these costs are quickly recouped through energy savings, resulting in the lowest total cost of ownership for agricultural lighting options.

LEDs in poultry farming

At the 2014 Strategies in Light event, Once Innovations president Brian Wilcox gave a presentation on “How to make chicks happy,” exploring compelling science which supports the claims that LED lighting’s economic benefits stretch beyond reduced energy costs to truly produce positive results — and therefore enhanced revenue — in poultry management and production. Here we will visit the poultry application in more depth.

While the ability to efficiently and accurately replicate sunlight gives LEDs an advantage over other agricultural lighting options, it is their ability to deliver a customizable, tunable spectrum that may be their greatest strength. The spectral sensitivity of animals differs from that of humans, and so too do their spectral requirements. By optimizing the use of spectrum, irradiance, and modulation in their barns, farmers can create a lighting environment for their animals that increases health and wellbeing, thereby enhancing growth while minimizing expenditures of energy and feed.

One of the most promising applications for agricultural LEDs is the lighting of poultry barns, primarily due to the profound differences in the way that humans and fowl absorb, detect, and react to photons. By exploiting these differences, LED-based technologies can lower luminaire cost, increase musculoskeletal development and weight gain, induce earlier maturity in layer chickens destined to produce eggs, improve feed conversion, alter melatonin production, increase egg ouput and quality, regulate reproductive cycles, and increase length of reproductive life.

Humans are tri-chromants with sensitivity to red, green, and blue spectral energy. Humans have peak sensitivity at 550 nm (green), trailing off significantly into the red and blue spectrum. Relying entirely on retinal reception, humans absorb photons through the photo-pigments rhodopsin (rods), iodopsin (cones), and melanopsin.

Fowl also absorb photons retinally through rods, cones, and melanopsin. However, they also absorb photons through functional photoreceptors located in the pineal gland on top of the brain (pineal reception). What is even more amazing, they even absorb photons through deep encephalic photoreceptors (hypothalamic reception).

Domestic fowl are quad-chromants. Like humans, fowl developed a peak sensitivity to green at 550 nm. But they also have enhanced sensitivity to reds, blues, and ultraviolet (UV) light. This is thought to be due to their origins. The tropical jungles of South Asia have a filtering effect on the light due to the green leaves in the tree canopies. Thus, fowl developed enhanced sensitivity to blue and red with peaks at 450 nm (12x human sensitivity) and 640 nm (4x human sensitivity). But probably the most dramatic difference between humans and fowl is the ability of fowl to perceive UV light retinally (peak at 385 nm). The reasons why domestic fowl can see UV light are largely under investigation. Two main suspects are food and flock recognition capabilities.

Each color has a distinct effect on fowl physiology. Green light, for example, significantly increases growth rate at an early age by enhancing proliferation of skeletal muscle satellite cells. Blue light increases growth at a later age by elevating plasma androgens. Narrow-band blue light reduces locomotion. It also reduces cannibalism rate at late age (especially in broiler chickens raised for human consumption). Together, green and blue light promote myofiber growth due to more effective stimulation of testosterone secretion. Overall, blue light has been shown to improve feed conversion by up to 4%, thereby reducing the cost per pound by up to 3% and increasing overall live weight by up to 5%.

Red light stimulates and promotes sexual activity and increases growth rates for chickens and turkeys at the beginning of the rearing period. It also increases locomotion, thereby minimizing leg disorders at the end of the rearing period. Red light also reduces the amount of feed consumption per egg laid with no differences in egg size, shell weight, shell thickness, or yolk and albumin weights. Overall, red light has been shown to lengthen the peak production period and increase egg production by up to 38 eggs per hen, while potentially decreasing food consumption by up to 20%.

Energy savings key to profitability

On-farm lighting is a significant portion of overall energy consumption. Agriculture facilities have similar lighting systems, are concentrated in a relatively small geographic area, are easily converted, and respond well to rebates. According to the American Council for an Energy-Efficient Economy (ACEEE), a $1B (billion) annual energy savings opportunity exists in the agricultural sector in North America, primarily in the Midwest. That is the equivalent of two nuclear power plants. According to Kate Farley of the ACEEE, 7% of on-farm expenses are energy related. Switching from incandescent bulbs to LED lighting could deliver an energy savings of $2000 per barn — a savings that can be sweetened with rebates, grants, and other funding, and go a long way toward making each barn profitable for farmers.

Consider the energy savings in the layer market alone. Nationwide, there are more than 2500 egg layer facilities, with six of the top ten egg producers located in the Midwest. On average, each layer operation utilizes 800 incandescent lights per facility. Replacing these lights with LEDs would yield a savings of 800 lights × (9W – 3W)/light × 16 hours/day × 365 days per year, or 28,032 kWh per operation. With 42% of the layer operations in Iowa, Ohio, and Indiana, that accounts for a 70M (million) kWh savings in these three states alone.

The savings are even more pronounced for the broiler market, which uses four times more energy than the layer market. The majority of these are across the Southeast and South Central states with many still using outdated lighting technology. Incandescent light energy consumption for broiler farms averages 271,814 kWh per farm per year, based on 4 barns/farm × 132 lights/barn × 100W/light × 18 hours/day × 52 days/flock × 5.5 flocks/year.

Dr. Joey Bray of Steven F. Austin University in Nacogdoches, Texas computed the energy savings by comparing Once Innovations’ AgriShift LED technology with existing incandescent and HPS lights in a production setting. In Bray’s broiler study, the average broiler farm with a standard incandescent/HPS solution consumed 3837 kWh per flock per year. The same farm equipped with AgriShift LEDs consumed just 109 kWh, a savings of greater than 95% per farm per flock. Applying this across the industry could equate to a total national energy savings of 2B to 5B kWh, or the entire output of one nuclear power plant. For more details on Once Innovations and AgriShift, see “LED agricultural solution uses driverless AC design.”

The energy savings are equally impressive for pork producing operations. Eight of the top ten swine states are located in the Midwest, with total light sockets (mostly CFL) of 1.8M. If all swine lights in the Midwest were replaced with LEDs, 52.2M kWh (CFL) – 25.2M kWh (SSL) = 27M kWh × 20 hours/day × 365 days = 540M kWh could be saved.

Standards and rebates

Despite the higher efficiency, effectiveness, and lower total cost of ownership of LED-based agricultural lighting products, high upfront costs have been a stumbling block. This is partly due to a lack of performance standards for the agricultural lighting industry, the absence of which makes it difficult for consumers of LED-based agricultural lighting products to take advantage of the energy savings rebates like those utilities offer for the incandescent and CFL lighting products used in consumer and commercial applications.

Current lighting standards focus on lighting performance and requirements as they apply to humans in residential and commercial applications. Energy-efficient consumer lighting products carry the Energy Star label, commercial products the DesignLights Consortium (DLC) label. Unfortunately, there is no comparable performance standard and label for agricultural lighting products. This makes it challenging for utilities to specify these products in their rebate programs, which in turn puts these products at a decided cost disadvantage. Farmers can still obtain a rebate by utilizing general-purpose consumer and commercial lighting products and retrofitting them for their barns (including having to enclose them in rugged or wet-location-rated fixtures), but off-the-shelf lighting products designed specifically for animals and barn environments generally do not qualify.

What suppliers and consumers (e.g., farmers) of agricultural lighting products need is a program that rates lighting products specifically with regard to agricultural performance. Such a program, which could be incorporated as part of Energy Star or DLC or even exist independently, would give consumers and power companies the information they need to compare agricultural lighting products while leveling the playing field for rebates. Ideally, the standard would provide uniformity across multiple utilities and address key performance criteria such as durability, performance, reliability, and safety. Efforts at creating such a standard are already underway, with several utilities having already expressed an interest in joining.

Pushing the future of farming

The majority of R&D efforts are focusing initially on the poultry and swine markets, but Once Innovations’ technology in particular can also be applied to dairy cattle, horses, and aquaculture. Swine, cattle, and horses, for example, cannot see red light, so dimming to a red spectrum at night enables workers to service the barn without disturbing the animals. A similar approach is used with humans in hospitals, where red light allows hospital staff to move about at night without the need for white light that would curtail patient melatonin production and interrupt sleep. (For more on lighting used in healthcare, see "Solid-state lighting brings out the true colors of modern healthcare" from this issue.)

Tailored spectra also have application to fish and crustaceans, where they can be used to control the pond environment. Once AquaShift lighting systems, for example, have been installed in commercial ponds in China and Belize, and university studies gauging the effect of LED lighting on crustacean productivity are ongoing. Global market potential for solid-state agricultural lighting is in excess of $17B. That will only increase as LED providers find new ways to harness light to enhance animal wellness and increase farm production while reducing energy utilization and costs.

KEN MARRIN is a contributing editor with LEDs Magazine.

LED agricultural solution uses driverless AC design

Regardless of formal performance specifications and rebate incentives, companies like Once Innovations are moving forward with energy-efficient LED-based agricultural lighting that improves animal wellbeing and enhances production at a reduced cost.

Once proprietary technology improves upon generic white LED technology by using a color-mixing approach that combines monochromatic colors to enhance reds and greens and produce a more uniform, tunable, dimmable light across the entire spectrum (Fig. 1 here). The conventional RGB arrays used in displays are driven by pulse-width modulated DC pulses; the turn-on time for each LED is controlled, varying the duty cycle of the DC pulses. AgriShift, by contrast, utilizes a proprietary stepped AC voltage to directly drive its LEDs. This approach eliminates the need for an AC/DC switch-mode driver and EMI filter, thereby reducing cost and space while increasing reliability. The low-EMI approach is also important from an animal welfare perspective, since all birds (fowl included) are extremely sensitive to EMI noise.

The AC technology used in the AgriShift product is unique in that it employs a simple analog topology to accomplish a somewhat complex objective. By organizing the LEDs in strings at various predetermined voltage levels, and coupling that with a proprietary switching FET, the circuitry eliminates complex digital switching circuitry that would otherwise be needed to construct the proper driving current waveforms. In essence, the LEDs create their own current waveform in reaction to the AC voltage being applied. By varying the type of LEDs in each string (using a combination of monochromatic color and white) and applying different voltage levels, the color spectrum can be varied. This architecture makes it easy to implement a color-shifting light fixture using traditional dimming technologies. It also avoids the complex DC control circuitry traditionally used in color-changing lighting systems. The resulting light fixtures interact very well with existing barn lighting control systems, which makes it easy for farmers to convert to the new technology.

AgriShift lamps are dimmable from 2% to 100%, including a sunrise/sunset mode that shifts the spectrum toward red when the lamp is dimmed. With no dimming, the lamp produces a full spectrum, which is ideal for stimulating growth during early chicken development (brood lighting). During grow-out, dimming can be decreased to 30%, with blues and greens remaining to promote muscle growth, and enhanced reds removed to reduce locomotion. Moon lighting utilizes full dimming, with monochromatic blue used to calm chickens, reduce aggressive eating habits, and facilitate catching. Fig. 2 here shows the spectral shift from white to monochrome that occurs when dimming an AgriShift VOBF (Variable Output Broiler Fixture) poultry lamp with a standard triac dimmer.

AgriShift lamps consume just 2–14W while generating 200–950 lm with greater than 97% power factor and less than 20% total harmonic distortion (THD). The low THD is another advantage of the analog AC topology, which provides graceful transitions and tames transient responses. The individual lamps are configurable with a variety of LEDs, form factors, and input voltages depending on the animal behavior being addressed.