Accurate thermal simulation enables LED lighting products to match design goals (MAGAZINE)

To realize the form factor, performance, and reliability goals in SSL product development, design teams should perform thermal simulation early in the development cycle, writes TOM GREGORY.

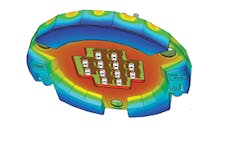

The explosive growth of the LED lighting market in recent years has been driven by a number of factors, not the least of which are green legislation and environmental concerns. LEDs are far more efficient than conventional light sources such as incandescent lamps, are more environment-friendly than fluorescent lamps because they don't contain mercury, and can be tuned for both color and brightness. So, LEDs are very flexible light sources for professional, industrial, and consumer applications, but the design of solid-state lighting (SSL) products is a complex multidisciplinary problem. Here we will focus on the thermal challenge and how simulation can help development teams deliver products that match reliability, form factor, and performance goals (Fig. 1).

Indeed, the promised operating life of LED lamps — usually somewhere between 25,000 and 50,000 hours — has not always materialized and SSL product performance sometimes deteriorates over time. Performance (quality and quantity of light output, operating life, color maintenance, and other parameters) is closely linked to the temperatures experienced within a lighting fixture or replacement lamp. For a given environment, temperature is directly related to how effectively the design of the fixture can dissipate internally-generated heat.

Design challenges

Two other related factors have an effect on long-term reliability in LED lighting: the aluminum electrolytic capacitors employed for energy storage in LED driver circuits, and the market demand for lighting manufacturers to create ever-more compact fixtures and lamps.

© Future Facilities Limited; restricted use.

FIG. 1. Thermal simulation of an A-lamp side-by-side with the finished product shows how simulation helps a team to meet design goals including form factor.

With the exception of electromechanical components such as fans, aluminum electrolytic capacitors are notorious for being the life-limiting components in many electronic circuits. The capacitors are electrochemical devices in which a wet electrolyte is gradually used up to reform an aluminum oxide dielectric layer during normal operation. The capacitors ultimately dry out and fail catastrophically. In high temperatures the process is accelerated.

Smaller lighting fixtures are needed in professional applications such as entertainment lighting so they can be transported and handled more easily and are less obtrusive in use. In retrofit applications — everything from street lamps to domestic downlights — there is a need to keep sizes and shapes within the limits defined by older lighting technologies. This normally includes cramming the electronic driver circuit inside the fixture, as well as the LED emitter module and lenses, in the case of directional lighting.

Fitting driver circuits

LED driver circuits are needed to convert the AC grid voltage to the low DC voltage needed to power the LEDs, and to ensure that they're driven for maximum output in an efficient way. Despite their high efficiency, LED chips (the "die") do generate heat, as do components in the driver circuit, particularly power transistors. When you put all the heat-generating parts in a small space to meet physical design limitations, things can get very hot very fast, even to the point of exceeding the typical 100°C maximum temperature that an LED junction can withstand.

The challenge for LED fixture and lamp designers is how to fit everything into the available space while ensuring that temperatures at critical points both inside and outside the final product remain within acceptable limits. That's where thermal simulation, especially when applied throughout the design process, can help. Fig. 2 is an example of chip modules under thermal simulation that display good thermal management.

Thermal simulation benefits

Historically, much of the design and development work has been done based on using rules of thumb to calculate from a thermal perspective how a particular component, printed circuit board (PCB), or complete assembly might perform. As the design and development process for any electronic product is iterative, the calculations have to be repeated throughout the product development process. At each stage, design errors need to be corrected and even then hotspots can be missed. Every change adds time and expense to the project, adding to the risk of missing windows of opportunity in the market.

Furthermore, the relatively poor accuracy involved in this approach results in designers having to over-engineer thermal management. As an example, this could mean using a larger heat sink than necessary, adding size and cost to the end product. It may even mean including a fan where one is not required, greatly reducing the final product's mean time between failure (MTBF), a measure of expected operating life. Perhaps even more important, it could result in thermal issues that don't manifest themselves until the product is already in the field. The potential costs of warranty claims, product swap-outs, and damage to brand reputation can be catastrophically high.

So, thermal simulation enables engineers to design smaller, more economical products that perform better and last longer. Thermal simulation offers the added benefit of being able to iterate the design rapidly, trying multiple options in thermal management and ultimately cutting time-to-market.

© Future Facilities Limited; restricted use.

FIG. 2. Thermal simulation shows that these chip modules display good thermal management characteristics.

Simulation in the development flow

The earlier in the design flow that thermal simulation is carried out, the lower the risk of having to make significant design changes to overcome thermal issues that may arise. Throughout the project, electronics, mechanical, and thermal engineers need to work cooperatively to ensure that the results of thermal simulations are taken into consideration in the design process, and that the impact of design changes on thermal performance are fully appreciated. Fig. 3 depicts the interaction between the team members with different disciplinary backgrounds.

At the start of the process, a very simple concept model — where all the electronic components are represented as a lumped block of heat — may be used to determine if it is possible to cool the lighting fixture within the constraints of its outline specification (Fig. 4). The total power dissipation of the product, its dimensions, the size of the heat sink, and the airflow of a fan — if one is to be used — represent all the information that is available at this stage.

At the next stage, when the preliminary product design has been created, the thermal modeling tool needs the following information to create a usable simulation:

• Details of components and their location on the PCB

• Estimated dissipation of the most significant components

• Dimensioned outlines of the lighting fixture housing

After running a simulation, temperature plots highlight where components are likely to exceed their maximum permissible operating temperature.

Input data drives results

The more accurate the input data, the more accurate the simulation will be. The results of the initial simulation can guide PCB designers and mechanical engineers toward changes that may be beneficial to the thermal performance of the fixture or lamp. The process is repeated as the design evolves.

The proposed final design should then be simulated again, before a prototype is produced. More detailed information is needed in order to ensure that the results of the simulation are accurate. This includes:

• Thermal models of components within the fixture, where these are available from component manufacturers

• 3D CAD models of the housing of the LED fixture or lamp - these can be imported into the simulation tool in a variety of industry-standard formats

• PCB designs from EDA software - these can be imported using industry-standard formats such as IDF and IDX

• Details of copper traces within the layers of PCBs

• Information about the characteristics of the materials used in the fixture

• Updated data on the expected power dissipation of components within the fixture, derived from engineering calculations

Once a prototype is completed, the development team verifies the accuracy of the simulation with physical temperature measurements. In evaluating this data, it's important to take account of the accuracy limits of the measuring devices employed. These may be thermocouples, on-chip sensors, or infrared sensors, depending on the application.

© Future Facilities Limited; restricted use.

FIG. 3. For thermal simulation to be of value, electronics, mechanical, and thermal engineers need to work cooperatively during product development.

Accuracy of thermal simulation

A thermal design specialist from Optimal Thermal Solutions BV, Norbert Engelberts has worked on a number of LED lighting projects using the 6SigmaET thermal simulation tool from Future Facilities. The first was the design of an LED lamp to replace 60W incandescent E27-base A-lamps for the European market. The design goal was to achieve the lowest possible heat sink temperature with convection cooling in order to maximize the operating life of the bulb. Operating life decreases as temperature rises. Thermal modeling was used to optimize the heat sink design and when the final product was evaluated, the simulation was found to be accurate to within 5% of measured temperatures.

The same degree of accuracy was encountered when designing a downlight. Here, the design goal was to determine the smallest possible heat sink that could be used while ensuring the LED junction temperature stayed well within its 100°C limit. The overall discrepancy between measured and simulated temperatures was just 4.6%.

© Future Facilities Limited; restricted use.

FIG. 4. Simulating a simple concept model determines whether it is possible to create a thermally viable product within the proposed mechanical and electrical constraints.

Engelberts also used thermal modeling in the development of a street lamp. The challenge here was to ensure effective thermal management within an IP66 sealed enclosure, the size and shape of which was determined by that of the conventional lamp that it was to replace. The weight of the lamp was a key concern, so the heat sink again needed to be kept to a minimum size, without unduly compromising the product's operating life. From the initial design to the final one, the average temperature at various points within the lamp was reduced by 19%, and at some points cut by 35%. The final product was just 13% heavier than the conventional lamp it replaced and, of course, far more reliable and energy efficient.

Thermal simulation tools

Thermal simulation tools for electronics design are based on computational fluid dynamics (CFD). Two tools suited to LED lighting design are Mentor Graphics' FloTHERM and Future Facilities' 6SigmaET. FloTHERM has been around for over 25 years while 6SigmaET is a newer tool designed to appeal to both experienced thermal engineers and those with less specialist knowledge.

Because the primary purpose of adopting thermal simulation is to create better products faster, key considerations in tool selection must include ease of use, particularly with respect to how easily the tool imports CAD models and facilitates model creation, and how quickly and accurately it performs simulations. The training and technical support from the vendor should also be evaluated. The duration of training courses can be a useful guide to the relative complexity of the tools.

TOM GREGORY is a product specialist for 6SigmaET (www.6sigmaet.info) at Future Facilities in London, UK.