GUV SNAPSHOT | The growing opportunity for GUV air disinfection

Providing good indoor air quality (IAQ) in buildings has become a national priority given the impacts on public health, education, and climate change. The COVID-19 pandemic raised awareness that our nation’s commercial buildings are often under-ventilated and lack adequate protection for workers and students from airborne diseases such as COVID-19, influenza, and respiratory syncytial virus (RSV). The resulting effects are significant. In the first half of 2023 alone, with the pandemic declared over, more than 40,000 people died from COVID-19 in the United States. Beyond the tragedy of deaths are the implications of millions of people becoming sick and missing school or work. According to a comparison of U.S. Bureau of Labor statistics from 2020–2022 versus 2019, absenteeism due to illness remains up ~50% from pre-pandemic levels, costing U.S. businesses over $200 billion annually. Absenteeism also reduces student learning and achievement and exacerbates public health and education inequities.

Two organizations recognized the impacts and the lack of protection in buildings and released new guidelines to address both issues. First, in May 2023, the Centers for Disease Control and Prevention (CDC) announced guidelines recommending that buildings aim for 5 equivalent air changes per hour (eACH) of clean air to reduce airborne disease transmission. As a point of reference, many commercial buildings may have only 1–2 eACH of clean air ventilation. Second, in July 2023, ASHRAE released Standard 241: Control of Infectious Aerosols. This new ASHRAE standard is expected to be incorporated by reference into commonly adopted codes and standards over time — increasing its use in new and existing buildings — although states and municipalities can choose to adopt this into their building codes and policies sooner. ASHRAE 241 sets clean air targets using a new metric called Equivalent Clean Air (ECA), with the recommended ECA varying by application and projected room occupancy. ASHRAE 241 establishes targets at 1.5–10X the amount of equivalent clean air ventilation in a typical commercial space compared to previous ASHRAE ventilation targets.

Increasing building clean air ventilation from 1–2 eACH to 5 eACH to meet CDC guidelines, or by 1.5–10X to meet ASHRAE 241, would result in large increases to building energy use and carbon emissions if met through traditional ventilation-only approaches. Moreover, most HVAC systems are not equipped to increase ventilation without costly investments, upgrades, and/or replacements.

Fortunately, with this in mind, the CDC and ASHRAE intentionally used technology-neutral, normalizing equivalency metrics of eACH and ECA that can be calculated for air-cleaning technologies including filtration and germicidal ultraviolet (GUV). Through this approach, the eACH or ECA targets can be met by a combination of traditional ventilation approaches with GUV. The eACH or ECA is calculated for both and combined to achieve the new targets. Therein lies the opportunity for GUV: A well-designed and maintained GUV system can deliver 10 eACH or more at a lower cost than a major HVAC upgrade at a fraction of the energy consumption and carbon emissions of equivalent ventilation.

With these benefits, it is expected that building owners and operators will consider GUV as a more affordable, effective, and energy-efficient solution to meet CDC and ASHRAE recommendations. Fully realizing these benefits will require continued technology and infrastructure development to support safe and effective GUV deployment. The U.S. Department of Energy (DOE) has several activities underway to validate the GUV opportunity, which will be outlined in this article.

Characterizing and quantifying GUV effectiveness, energy, and carbon reduction benefits

To consider and include GUV in projects, building owners and designers will need to know how effective it is and quantify its benefits. Pacific Northwest National Laboratory (PNNL), in collaboration with Lawrence Berkeley National Laboratory (Berkeley Lab), uses sophisticated simulation tools to characterize and quantify effectiveness, energy efficiency, and decarbonization benefits of GUV in achieving CDC and ASHRAE 241 guidelines across building types and climate zones.

We are able to model dynamic pathogen concentration levels, infection risk, and energy use. We can then alter disease transmission characteristics, pathogens, combinations of mitigation strategies, and climate zones, varying the inputs and assumptions. Simulations will help us determine which IAQ strategies including GUV will result in the healthiest and most energy-efficient buildings. We will share results of this work in an upcoming article.

Testing GUV products

Some readers may remember DOE’s CALiPER product testing program, which operated from 2006 through 2014 to evaluate LED products during the wild-and-woolly early days. CALiPER provided independent testing of commercially available products and published its findings to discourage inferior quality and inflated claims — a need that exists again with GUV technology.

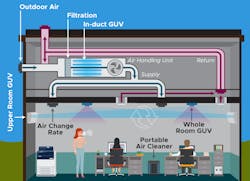

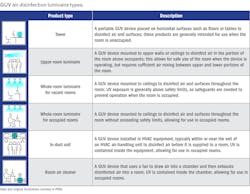

The predominant GUV technology is low-pressure mercury (LPM), which has been used in health and institutional settings for decades. New technologies have emerged including UV-emitting LEDs and krypton-chloride–based (KrCl) excimer lamps. Standardized test methods for GUV products are also just emerging. Some products are designed for occupied rooms, while others should not be used when a room is occupied.

One round of product testing is complete and rounds 2 and 3 are underway — testing upper-room luminaires using LPM (254nm), LED (260–280nm), and KrCl excimer (222nm) luminaires for occupied spaces. We will be detailing the results in a future issue of LEDs Magazine, with these new data sets informing testing methods and standards, and identifying needed improvements to GUV technology.

Validating in-field performance

Upper-room GUV radiates across a room near the ceiling as air circulates through it. Whole-room GUV radiates downward from the ceiling into the occupied area. PNNL is studying real-world existing installations of both system types to evaluate their effectiveness, safety, and energy use. This testing involves five upper-room and five whole-room installations. The study also includes two new GUV system installations, taking each from project conceptualization to design, installation, and ongoing operation and maintenance.

We’re looking to answer key questions in the field: Are installations safe and effective? How much energy does GUV use in real-world applications? How are GUV systems operated and maintained for ongoing effectiveness and safety? What is the occupant experience with the technology?

Field evaluations of these GUV installations are ongoing and we will report results in a future issue.

Unlocking the potential

The potential benefits of GUV extend well beyond the lighting industry. GUV applied to the nation’s building stock has the capacity to improve our health and safety while helping the country hit energy and decarbonization targets that can have a meaningful impact on climate change. Stay tuned; we’re just beginning.

GABE ARNOLD, P.E., is a senior systems engineer with Pacific Northwest National Laboratory (PNNL), where he leads programs to support the development and adoption of emerging lighting and building technologies.

Follow our LinkedIn page for our latest news updates, contributed articles, and commentary, and our Facebook page for events announcements and more. You can also find us on the X platform.

Gabe Arnold

GABE ARNOLD is a senior systems engineer at Pacific Northwest National Laboratory (PNNL), where he supports the U.S. Department of Energy’s Lighting R&D and Commercial Buildings Integration programs in the development and deployment of emerging lighting and building technologies. In his current work he leads a research, development, and demonstration program for germicidal ultraviolet disinfection technologies and is also the technical lead for DOE’s L-Prize competition.

![The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.] The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.]](https://img.ledsmagazine.com/files/base/ebm/leds/image/2024/08/66be810888ae93f656446f61-dreamstime_m_265700653.png?auto=format,compress&fit=&q=45&h=139&height=139&w=250&width=250)