Understand the lighting flicker frustration (MAGAZINE)

Lighting control manufacturers are committed to reducing flicker, improving LED performance, and providing commercial customers with comfortable, efficient lighting and control solutions, but ETHAN BIERY explains that the lighting industry is still struggling to establish good metrics to characterize the temporal lighting artifacts problem.

The evolution of LEDs in the lighting market has not always been smooth, but the technology has come a long way since the early days. As LED technology matures, each generation raises the bar, driving users and manufacturers to deliver higher performance and more flexible control options. Manufacturers also continue to address customer concerns by improving color quality, product price, lifetime, efficiency, and dimmability. Still, lighting flicker remains as an issue that the industry must fully understand, and account for in solid-state lighting (SSL) and control products, enabling safe and comfortable LED-based lighting for humans.

Interested in more articles & announcements on LED standards, test & measurement?

New standards are developed, manufacturing processes are improved, and manufacturers continue to look for ways to boost product performance and differentiate themselves from the competition. The next big performance debate is now centering on flicker. Complaints about flicker are nothing new to the lighting industry; however, the specific characteristics of LED lighting present some unique challenges.

The simplest definition of flicker is "modulation of light output." This basic concept, however, obscures many of the complex characteristics that ultimately make flicker difficult to quantify. And, while flicker in electric lighting is generally considered undesirable, there are situations - especially with organic light - where flicker can add a distinctive atmosphere to lighting. Consider, for example, the flicker of a candle or the reflection of sunlight off the water. For the purposes of this article, we will focus on the undesirable aspects of flicker created by electric lighting.

Defining the problem

Beyond just modulation of light output, it's important to distinguish several classifications of lighting flicker:

- Visible flicker: modulation of light, whether periodic or intermittent, which most users can see as a change in the light output, even under static circumstances

- Stroboscopic flicker: the periodic modulation of light due to an inherent characteristic of the power source being used, which is perceptible only if the light source moves or the user's head moves

Consider that while complaints are usually associated with reactions to visible flicker, the two are not mutually exclusive: Stroboscopic flicker can be visible or invisible.

Even under normal operation and ideal conditions, traditional light sources, such as incandescent lamps, exhibit stroboscopic flicker. An incandescent lamp operating at 60 Hz (in North America) experiences a voltage decrease that reaches zero 120 times a second (twice per line cycle) - the lamp's filament cools, reducing the light output. However, the thermal mass of the filament prevents it from cooling much in the 8 milliseconds or so before the voltage begins to rise again. If measured carefully, this flicker can be detected but is almost never a source of user complaints (Fig. 1).

FIG. 1. Even a legacy incandescent lamp exhibits measurable flicker as the AC power line crosses the 0V level.

Compare the incandescent lamp with the magnetically-ballasted fluorescent lamp. In this case, the lamp extinguishes and reignites 120 times per second when dimmed. Fluorescent lamps do not have a thermal mass that needs to cool, and extinguish their light in about a millisecond (much quicker than incandescent lamps). The flicker in magnetically-ballasted fluorescent lamps is still noticeable, and may cause people who work under such light to experience more subtle effects of this stroboscopic flicker, including headaches, eye strain, and discomfort, even if it is not directly visible. Fortunately, high-frequency electronic ballasts, most of which operate around 40 kHz, have all but eliminated the issue of stroboscopic flicker with fluorescent lamps (Fig. 2).

FIG. 2. High-frequency electronically-ballasted fluorescent lighting essentially eliminated flicker as a problem in such products.

As you may have perceived by now, flicker is not just an inherent property of the light source being used; it is a property of the light source in combination with the associated electronics, such as ballasts for fluorescent lamps or drivers for LEDs.

Furthermore, the addition of non-ideal power, caused by sources of electronic noise common in the real world, further contributes to the observed amount of flicker.

How are LEDs different?

Unlike other light sources, LEDs have no inherent ability to continue to create light once current flow stops - they have no persistence. When the current flowing through an LED goes to zero, its light output goes to zero - typically in mere microseconds. For example, LEDs are often used for high-speed fiberoptic communications because of this particular characteristic. Flicker is a function of the light source and the stability of the associated electronics; therefore, any fluctuation in the power source to the LED could become instantaneous fluctuation in the light output or flicker.

The question can come down to how much flicker is acceptable, and how much is problematic? Even under ideal circumstances, the amount of observable flicker in a given application can change based on many different variables:

• The frequency of the flicker, and whether it is periodic (stroboscopic) or not

• The wave-shape of the flicker

• The age and visual acuity of the observer

• The overall light level

• Position, intensity, and possible synchronicity of other light sources

• Relative motion of the observer, light source, and/or nearby objects

All these factors start to explain why it's difficult to come up with one correct, universally accepted, quantifiable response to the question: Does the light source flicker?

Adding dimming to the mix adds yet another variable. Not only does a dimmer reduce the light levels, creating an environment where flicker is more readily apparent, it adds another potential source of instability. Even slight variations in the stability of an analog dimmer, whether phase-control or 0-10V, can produce flicker in an LED driver. Poor-quality LED drivers, or drivers that are not designed and tested to deliver reliable dimmer compatibility, are especially prone to causing LED flicker. Using dimmers specifically designed and rigorously tested for use with dimmable LEDs can often improve dimming performance and minimize or eliminate flicker to the greatest extent allowable by the driver.

Existing work

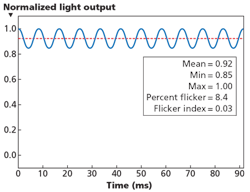

Much groundwork has already been laid in the area of flicker measurement. Most flicker measurements start with a photodetector that is capable of high-speed measurement, and that closely matches the spectral sensitivity of the human eye. The photodetector is connected to an oscilloscope or other instrument that captures and records the resulting electrical signal at high speed for example collecting thousands of samples per second. The resulting waveform can then be processed under several different algorithms to create flicker metrics, currently the most common of which are "Flicker Index" and "Percent Flicker", which are defined in the IES Handbook.

Consider Fig. 3 to understand the metrics that are based on the following equations:

Flicker Index = (Area 1)/(Area 1 + Area 2)

Percent Flicker = 100% × (Maximum Value - Minimum Value)/(Maximum Value + Minimum Value)

While both of these values are relatively easy to measure and compute, they have a few shortcomings. First of all, the values are computed independent of frequency. A light source that flickers at 10,000 Hz, which is well beyond the visual acuity of human vision, has the same value as a light source that flickers at 10 Hz and is clearly visible by all. Furthermore, these metrics are unsuitable for trying to capture intermittent or transient flicker, but are instead best used for comparing light sources with periodic waveforms at the same frequency. Work by the US Department of Energy yields more information on this topic.

Because of these flaws, most testing for flicker is done through subjective observation: having trained observers, who are known to have good visual acuity, observing a light source under controlled conditions. Not surprisingly, this frequently results in differing answers to the question "does it flicker?" The answers typically depend on the observer, which makes it particularly hard to reproduce results between different test locations. Another potential concern is that stroboscopic flicker beyond the range of visible frequencies, which may contribute to non-visual discomfort, is not specifically measured using these testing methods. Despite these shortcomings, subjective observation is still the method currently available that best reflects the customer's behavior and expectations in the field.

FIG. 3. Flicker Index and Percent Flicker metrics defined for LED lighting only partially address the potential issues of flicker in SSL.

Newer flicker measurement techniques try to overcome the shortcoming of the Flicker Index and Percent Flicker methods, while matching the practicality and usefulness of the visual observation method. These more advanced algorithms still use the same waveform measurement but tend to factor in frequency-specific measurements. They often include taking the FFT (Fast Fourier Transform) of the signal, which allows a complex waveform, even if not periodic, to be analyzed as a sum of individual frequencies. This methodology allows these algorithms to apply specific weights, or importance, to frequencies of interest - for example, frequencies that are more likely to be visible, or that will cause headaches and discomfort. In theory, the measurements allow researchers to account for both stroboscopic flicker and transient flicker, and can allow for differing thresholds based on application - high-performance architectural lighting versus street lighting, for example.

Current research

The Rensselaer Polytechnic Institute Lighting Research Center (LRC) was an early advocate of analyzing fundamental frequencies responsible for causing flicker. Their Recommended Metric for Assessing the Direct Perception of Light Source Flicker (January 2015) utilizes this approach, and associates the resulting value with a probability of whether or not flicker will be detected by a typical observer.

The most recent development in the area of flicker was the publication of IEEE 1789-2015, IEEE Recommended Practices for Modulating Current in High-Brightness LEDs for Mitigating Health Risks to Viewer. This comprehensive, and unexpectedly controversial, document was developed over the course of several years, surveying and combining the results from many previous studies on flicker (see prior LEDs Magazine coverage). Like the LRC work, the IEEE recommendations also acknowledge the effects of flicker frequency. Its recommendations provide some application-specific guidance, giving frequency-dependent limits for "low risk" and "no effect" cases.

While many previous industry works on flicker focused primarily on visible flicker, the scope of the IEEE work emphasizes potential health risks. This subtle but important distinction attracted the close attention of manufacturers, who may have feared backlash if their products were associated with adverse health effects. Immediately following the IEEE 1789 publication, the National Electronic Manufacturers Association (NEMA) published a position paper on Temporal Light Artifacts (TLA). The TLA position paper admonishes the IEEE work as "overly strict," and also cites how other standards such as Energy Star are relying on inadequate flicker metrics such as flicker index. NEMA concludes the paper by describing a forthcoming standard being developed by the NEMA TLA working group, which will provide application-centric recommendations and test procedures specific to LED lighting.

Next steps

While not a new problem, recent developments in the lighting industry have brought the flicker issue to the forefront for many designers and manufacturers. At the same time, current and nascent industry standards do not adequately describe how to measure and quantitatively determine whether or not an LED light source (and its associated electronics, including drivers and dimmers) causes flicker. Forward-thinking manufacturers and regulatory bodies are committed to and actively involved with intense efforts to develop an improved, repeatable measurement metric. In the coming months, stay tuned for the results of this exciting work.

ETHAN BIERY is the LED engineering leader at Lutron Electronics Co., Inc. (lutron.com).