Understand the true cost of LED choices in SSL systems (MAGAZINE)

The LED component cost is only one facet of the design and production cost for solid-state lighting (SSL) systems. Other factors that impact the overall cost, performance, and lifetime of general lighting products include the suitability of components for the intended lighting application, thermal management, and packaging, explain RALPH TUTTLE and MARK McCLEAR.

The solid-state lighting (SSL) industry has focused on LED component cost as the key to lower upfront costs for LED-based lighting and broader deployment. And indeed lower LED prices are important for broader SSL adoption. Still, there can be hidden system-level costs and reliability issues tied to the selection of LED components, which SSL developers must understand to deliver products that perform well at install and throughout an extended life. Lengthy LM-80 testing of components is paramount to robust lighting products. Let's examine some background on LED manufacturing and trends, discuss SSL application requirements, and then consider how the hidden cost of LED components can impact the success of a general-lighting product.

We often hear remarks about how quickly LED technology is changing and the rapid pace of the so-called LED lighting revolution. But this apparent trend is underpinned by decades of product research and development and manufacturing capacity investment put in place to serve other, older segments of the LED market that came well before the LED lighting market segment emerged. The LED TV market is one such market segment, and an entire product and manufacturing infrastructure was quietly built up in 2010 and 2011 to supply LED chips and plastic LED packages to meet the anticipated demand of this relatively low-cost, low-performance consumer products market segment.

Metal-organic chemical vapor deposition (MOCVD) process tools are required for making LED chips of any kind. There was a massive wave of LED chip-making capacity that was put into place to support the anticipated demand of the nascent LED TV segment during this short 2010–2011 window. This additional capacity was more than the total industry capacity that existed before that time.

Similar investments in low- and mid-power plastic packaging capacity were made in the LED industry during this same timeframe; however, subsequent advancements in display panel technology have dramatically reduced the number of LED components required for a given display size, thus resulting in significant overcapacity issues in the industry. This stranded LED chip-making and packaging capacity has had a very positive and beneficial impact on the pricing of component LEDs, which has helped to accelerate the LED lighting revolution.

Mid-power LEDs in SSL

The rapid price decline has also tempted many to deploy these low-cost plastic LED packages designed for the consumer products market in LED lighting applications that have much higher expectations for quality and reliability. While the physical size, shape, and initial light output characteristics of LEDs designed for TV applications may appear similar to lighting-class LEDs, there are distinct differences between the two LED types: the materials of construction and critical long-term reliability metrics such as lumen maintenance and color stability.

Plastic low- and mid-power LEDs can provide a uniform and smooth lighting appearance in some white lighting applications such as LED panel lights, linear arrays, and T8-tube replacements where the maximum LED junction temperature (Tj) can be consistently maintained at or below about 70°C.

The low prices of these low- and mid-power plastic LED packages make them tempting choices for LED luminaire designers who are often faced with challenging cost and performance design constraints. The materials used in the construction of many low- and mid-power LEDs, however, can make them risky choices for the majority of general lighting applications where common LED junction temperatures can easily exceed 70°C. Cree frequently sees temperatures of 100°C in our Thermal, Electrical, Mechanical, Photometric, and Optical (TEMPO) testing services program.

Temperature impact

Now let's further consider the impact of higher temperatures. Polyphthalamide (PPA) is a thermoplastic resin that is frequently used as an electrical connector housing material in high-temperature automotive applications. It has the ability to withstand the high temperatures found in engine compartments without cracking or deforming. PPA is also the material used in most plastic-packaged low- and mid-power LEDs.

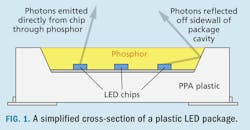

In addition to the light emitted directly from the chips in a PPA plastic LED package, a significant amount of the light is reflected from the bright white internal surfaces of the package cavity in which the LED chips are placed, as shown in Fig. 1.

One of the challenges with using PPA as the material for these LEDs is that, over time, the white surfaces discolor and darken when exposed to higher temperatures. Furthermore, the blue photons emitted from the LED chips used in phosphor-converted white LEDs cause additional discoloration of the PPA surfaces. As a result, during operation of the LEDs, the highly-reflective white surfaces in the package begin to absorb light, leading to considerable lumen depreciation of the LED.

LM-80 testing

Cree has performed extensive long-term lumen maintenance testing of both plastic and ceramic LED packages per IESNA LM-80-08, "Approved method for measuring lumen maintenance of LED light sources." LM-80 requires testing LEDs for a minimum of 6,000 hours and recommends testing for longer periods to improve predictive modeling of lumen maintenance. IESNA TM-21-11, "Projecting long term lumen maintenance of LED light sources," similarly recommends testing for times longer than 6,000 hours. An important aspect of TM-21 is the "6X rule," which limits the claims of usable lifetimes (L70) of tested LEDs to no more than six times the actual accumulated LM-80 test time. This rule exists because of concerns about instabilities of some LED packages, and also to minimize exaggerated lumen maintenance claims by LED manufacturers.

Fig. 2 shows the LM-80 test results of a typical set of mid-power (0.5W) plastic LED packages. These LEDs were tested at 85°C with a drive current of 175 mA. The upper graph shows the lumen output (% LF) of the data set and the lower graph shows the chromaticity or color-point shift (Δu'v') of the data set after 6,048 hours of testing. Using the method defined in TM-21 to project the lumen maintenance of this data set results in an L70 of approximately 43,000 hours — limited to a claim of 36,000 hours by the 6X rule. The average chromaticity shift is within a 7-step MacAdam ellipse as required by the US Environmental Protection Agency's Energy Star program, and these results would generally be judged as satisfactory — including by the Energy Star program — for most lighting applications.

A hidden cost of these low-cost plastic LED packages can come into play when the same devices are extended beyond 6,000 hours of LM-80 testing. Fig. 3 shows the same LEDs after more than 17,000 hours of LM-80 testing. Lumen depreciation has significantly increased due to the discoloration of the PPA material. As seen in the upper graph, the L70 life is rapidly declining toward less than 20,000 hours as a result of the light being absorbed in the LED package. An additional consequence of this material discoloration is the large shift in chromaticity of a nearly 20-step MacAdam ellipse, which would be unacceptable in almost any lighting application.

Color shift

This shift in chromaticity is a very serious, yet rarely discussed, issue with plastic LED packages. When a plastic LED package is first operated, light is emitted from the LED chips directly through the phosphor as well as being reflected internally off of the package walls, as shown in Fig. 4. The mean free path of these blue photons emitted directly through the phosphor will be shorter than the mean free path of those reflected off the walls of the package. Thus the color point of the light emitted directly through the phosphor will be cooler, with more blue energy, than the color point of the reflected light. Similarly the reflected light will be warmer, with more yellow energy, than the directly emitted light. The average overall color of the LED package will be the combination of all of the emitted light — both cool and warm. When the PPA discolors, the reflected light is absorbed by the walls of the package so the warmer component of the chromaticity is reduced, as shown in Fig. 5. The result is a significant shift in color point toward the cool end of the spectrum.

High-power LEDs do not suffer from the same lumen depreciation and chromaticity shift issues as plastic-packaged low- and mid-power LEDs. The ceramic substrates used in the construction of high-power LEDs are not used as reflective surfaces, so only the light emitted directly from the LED chip is critical to the initial or long-term lumen maintenance and color point (Fig. 6).

Even at high temperatures, lumen maintenance and color point stability far exceed those demonstrated by plastic-packaged LEDs. Fig. 7 shows LM-80 test data from a set of standard high-power Cree XLamp XP-E LEDs. Even after more than 11,000 hours of testing at 105°C, with a drive current of 350 mA, excellent lumen maintenance and color point stability is observed.

Changing the mid-power package

Due to the known limitations of using PPA resins as a packaging material for LEDs, Cree has developed a line of novel LED products that combines the advantages of traditional low- and mid-power LED products with the benefits from high-power ceramic LED products. The new Cree XH family of ceramic-based LEDs can give the same smooth lighting effect as plastic low- and mid-power LEDs but without the hidden color shift and reliability costs of traditional PPA-based plastic LEDs, originally designed for consumer applications.

Whether plastic- or ceramic-based, low-, mid- or high-powered, the common denominator and industry standard method for assessing the lumen maintenance potential for any LED component is via LM-80 testing. While 6,000 hours of LM-80 test time are the minimum requirements for making a lumen maintenance projection using the TM-21 method, longer LM-80 test times can yield more accurate predictions and help the luminaire designer reduce risk of lumen depreciation and color shift over time. As LM-80 testing continues on thousands of LED components — with millions of accumulated test hours — our understanding of degradation mechanisms continues to grow, as well as our ability to extrapolate laboratory test results to real-world lighting applications.

The low- and mid-power LEDs on the market today are largely a result of over-investment by the LED manufacturing industry in LED chip and plastic packaging capacity based on anticipated demand from the LED TV market. Beneficial results for the LED lighting industry have come in the form of an expansion of LED panel lights and T8 tube applications, and also a dramatic reduction in general LED component pricing. But the hidden cost of these low-cost plastic LEDs may come in the form of reduced reliability, diminished lumen maintenance, and poor color stability in the majority of common lighting applications where the LED junction temperature is often well above 70°C.

LED luminaire designers should ask their LED manufacturer for accredited LM-80 data reports — with data beyond 10,000 hours of test duration — and carefully compare these results to their anticipated application operating conditions.

Plastic low- and mid-power LEDs can be reasonable choices for some lighting applications but true lighting-class LEDs—generally based on ceramic substrates — have demonstrated superior lumen maintenance and color stability in the majority of lighting applications, and can deliver on the promise of long-term color, cost, and energy-saving performance.

RALPH TUTTLE is applications engineer manager and MARK McCLEAR is vice president, applications engineering, at Cree, Inc.