A century ago, the “War of the Currents” between AC and DC appeared firmly settled on the side of AC power distribution. AC supported much longer reaches and favored the native AC loads of the time, like arc lamps. DC loads such as DC motors required an AC–DC conversion stage, which reduced efficiency — the price of an interconnected power grid.

Today, the power transmission debate has begun to shift. An increased focus on renewable energy has led to proliferation of on-site DC power sources. The growing popularity of solid-state lighting, electric vehicles (EVs), and the Internet of Things (IoT) has caused the number of DC loads to skyrocket.

Rather than squander energy by converting the DC power generated onsite into AC power to route through the building, only to convert it back to DC within the connected devices, perhaps the time has come to rethink how we wire buildings for DC distribution. A DC microgrid approach has potential to increase efficiency, remove points of failure, simplify electrical wiring, lower cost, and boost resiliency. Best of all, it provides new opportunities for the LED ecosystem.

AC and DC basics

In AC electricity, current direction and voltage polarity change as a function of time. With DC electricity, current direction and voltage remain constant. Changing AC to DC requires a multipart converter built around a rectifier circuit, in addition to voltage reduction (step down) and filtering stages. They may be integrated into the device, as with an LED lamp designed as a direct replacement for conventional lamps; or in a separate power adapter, as with a laptop.

Converters raise cost and complexity, not to mention points of failure. According to a U.S. Department of Energy (DOE) accelerated stress test on LED drivers, 64% of devices failed as a result of AC-to-DC conversion circuitry.1 Perhaps most important, each conversion step imposes a power penalty of 5% to 10%. Multiply that by billions of DC loads around the world, and conversion loss becomes significant.

On the supply side, renewable energy sources such as photovoltaics (or their battery backups) generate DC power. To make it compatible with AC power distribution systems, the DC needs to pass through an inverter, which introduces another efficiency drop. At this point, the power is either returned to the grid or routed through wiring to the AC receptacles, where any attached DC device has to convert it back to DC.

DC microgrids provide an alternative. There are two ways to power a DC microgrid. One is direct DC power from renewable energy sources, like a solar array with fuel cell backup. The other is to use a centralized DC power hub to convert incoming AC from the grid to DC for use throughout the building. Conversion still occurs, but the converter itself has greater capacity and thus is more efficient; losses are on the order of 2 to 3%, compared to 10% or even 20% for device-level converters.

Why DC microgrids?

A number of factors are driving the interest in DC microgrids. Brian Patterson, chair of the EMerge Alliance, an industry association that promotes DC and hybrid AC/DC microgrids and power systems, points to LED lighting as the spark for the microgrid concept. “LED lighting really reignited the conversation about AC versus DC electricity, because LEDs are a fundamentally solid-state technology that natively wants to use DC electricity, not AC electricity,” he said.

Changing usage patterns: Although SSL may have been influential, it’s only part of a greater trend in equipment and appliances. Moving beyond EVs and the IoT, an increasing number of pumps, fans, and compressors used in HVAC systems depend on DC or AC motors powered by DC variable-speed drives. Computers are inherently DC, as are modern televisions and many appliances integrating DC motors. “We’re living in a DC world with an AC infrastructure,” said Dusan Brhlik, co-founder and CEO of Direct Energy Partners, a DC electrical infrastructure consultancy based in Aarschot, Belgium.

Resiliency requirements: That existing AC infrastructure is aging rapidly, with cabling and critical assets like transformers now operating well past their rated lifetimes. In addition, the grid is being overloaded by ever-growing demand. Utilities have had to adapt their already overtaxed grids to new operating modes. AC power grids were originally designed for one-way operation — pushing power from centralized plants out to customers. Today, customers with renewable energy sources want to push their excess power back to the grid, forcing utilities to retrofit their AC power distribution systems to support two-way operation. All of this is leading to a less reliable power grid.

Meanwhile, climate change promises to increase the frequency and intensity of severe weather events and natural disasters such as wildfires. As a result, energy independence has become increasingly important to commercial and residential sectors alike. A building or facility equipped with a renewable power source and a DC microgrid can disconnect from the commercial grid and operate as an “energy island” until the crisis has passed.

Government initiatives: Recognizing the importance of reducing carbon emissions and ensuring the continuing operation of the grid, governments at all levels have passed legislation packed with incentives and funding for clean energy. Other laws and directives have established efficiency requirements for devices ranging from lamps to motors. All of these efforts have a net effect of promoting DC microgrids.

Corporate sustainability commitments: Corporations have begun developing roadmaps to net-zero carbon in order to stay ahead of regulations. Switching to clean energy is an important part of staying on those roadmaps, and adopting DC microgrids is a natural step.

DC microgrids reduce carbon footprint in other ways. For example, semiconductor fabrication is a resource-intensive process. By eliminating the need for manufacturing power conversion electronics, DC distribution can reduce environmental impact over AC systems.

Cost savings: DC microgrids can reduce both capital expenditures (capex) and operating expenditures (opex). Wiring for AC distribution systems needs to be run in steel conduit and installed by electricians. Depending on the voltage level, DC power may not need conduit or a licensed installer, lowering costs. Low-voltage DC is compatible with Power over Ethernet (PoE), which allows power and data to be carried over a common Ethernet cable. Installing and reconfiguring is as simple as plugging the cable into the correct ports. Eliminating the emissions from mining, processing, and transporting conduit further reduces carbon footprint.

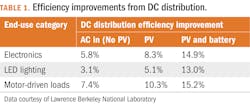

Opex frequently dwarfs capex, particularly in the case of building operations. Running native DC devices on DC power eliminates the need for AC-to-DC converters and the associated energy losses mentioned earlier. A study by Lawrence Berkeley National Laboratory (Berkeley Lab) and the National Renewable Energy Laboratory (NREL) showed substantial efficiency improvements for native DC loads on DC distribution systems (see Table 1).2

DC microgrid adoption is “going to be driven by the heating sector and the electrification of transportation,” said Gabe Arnold, senior systems engineer at Pacific Northwest National Laboratory (PNNL), which has also developed studies on DC power and lighting. “There’s just so much power involved that when you start to add 5 to 10% energy losses and the equipment that’s required to convert that much electricity, the cost savings are tremendous. So, eventually that’s going to overcome some of the barriers that we’re seeing.”

Barriers to DC microgrids

Those barriers appear mainly attributable to the lack of consensus on DC integration approaches and objective industry guidance rather than a lack of technology understanding.

Standardization: Any complex, interdependent technology like the electrical grid requires standardization to promote ease of deployment and interoperability while fostering an ecosystem. For DC microgrid technology, standardization is very much a work in progress.

“Even voltage levels are still not decided,” said Willy Bernal Heredia, research engineer at NREL. “In AC, we have our standard 120V, 480V, and so on. For DC, we’ve seen a number of different options. And that creates a little bit more friction for developing and implementing DC in buildings.”

The EMerge Alliance has developed two standards for power distribution systems. One is a low-voltage standard for occupied spaces, designed to support use cases like commercial offices. The specification is compatible with PoE and can be used with native DC power sources or DC power provided by a central converter hub. One architecture would be a ceiling-mounted distribution system that uses PoE cables to power LED light fixtures, sensors, workstations, and peripherals.

The alliance has also generated a 380V standard aimed at data centers and telecom central offices. Separately, the Current OS Foundation, another industry association, is developing open standards for DC microgrid control that are currently standardizing around 350V. That said, the two organizations have recently signed a collaboration agreement, so we may see some harmonization between their standards.

Also on the positive side, the 2023 update of the U.S. National Electrical Code (NEC) includes an important addition that could significantly speed the adoption of DC power. Maintained by the National Fire Protection Association (NFPA), the NEC provides the foundation for state and municipal building codes in the U.S. and a number of other countries. The latest update added a new power classification, Class 4, which specifies fault-managed power systems (FMPS) to address a serious safety concern with DC power distribution systems that prevented their use at higher voltages.

In an FMPS, the power is digitally monitored for anomalies. If there is a fault in the system, such as an arc flash, it will interrupt in milliseconds to prevent injury. This safety feature enables Class 4 power systems to safely operate with voltages as high as 450V AC or DC, creating the foundation for widespread adoption of DC-ready devices. Patterson, for one, is bullish on the technology. “I really believe that Class 4 power is going to change the world,” he said.

Changing the NEC is only the start. Once the latest version is released, states and municipalities need to review the changes, adopt them, and train inspectors — all of which takes time. “The National Electrical Code only gets revised every three years,” Patterson explained. “Municipalities sometimes lag three to six years behind that.”

For municipalities, updates to the code represent hard work. Authorities need to review changes, incorporate them in local building codes, and then train inspectors. This can sometimes lead to absurdities like the wiring in a DC-only building failing inspection because it lacks AC receptacles every 6 feet.

Lack of quantifiable data: Before architects, contractors, and building owners can decide whether a DC or hybrid AC/DC distribution system is viable for their building, they need reliable, impartial data. “You have to go beyond just efficiency numbers,” said Omkar Ghatpande, research engineer in NREL's Building Technologies and Science Cente. “There are other benefits that have to be studied. For example, DC power systems use electrochemical storage, which is inherently DC, so at lower cost, you can probably get better resilience and better reliability. But just saying ‘better’ is not enough, many times.”

The white paper from the Berkeley Lab/NREL team was designed to help address this gap. The authors analyzed available development case studies to assess performance and reviewed deployment strategies for effectiveness. Still, more work remains to promote DC microgrids from the demand side.

Lack of native DC devices: One of the barriers to DC microgrid adoption is the comparative lack of DC-ready products. Manufacturers are reluctant to make DC products unless there’s a market, but the market can’t develop without products to support it.

As part of their study, the Berkeley Lab and NREL teams assessed availability of native DC products, counting both products deployed in testbeds and for sale on the market (see Table 2). DC lighting was in use at virtually every location, while other products necessary to support the transition to a full DC grid are further from maturity. Once again, SSL leads the way.

“Based on the rate of adoption for solar and battery storage, the DC microgrid is not out in the future,” said Hanan Fishman, president of solar energy equipment provider Alencon Systems, in Hatboro, Pa. “It’s already the present. The load side is where we need more evolution, more solutions.”

The road ahead

The ultimate goal is to convert the current centralized AC grid to a self-healing mesh of native DC power sources. However, the transition won’t happen overnight. It will take years for DC microgrids to become the norm, even in new builds. Until then, hybrid AC/DC networks will provide a technological bridge.

That said, momentum for DC distribution systems is growing and the right stakeholders are paying attention. “Many of our systems are being specified by architects and engineers on DC projects,” said David Mandell, who leads business development at Marshall DC Lighting in Phoenix. “We get calls from electrical contractors who are bidding on projects that call for DC light fixtures and we have large-scale electrical distributors who are regular customers.” His company has experienced growth year-over-year for the past five years. “We thought we were going to get hit hard during COVID, but we actually experienced growth," he continued. "It made us very confident this move toward DC is not going away.”

REFERENCES

1. L. Davis and K. Rountree, “Accelerated Stress Testing Results on Single-Channel and Multichannel Drivers,” Developed for U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy (2019).

2. V. Vossos et al., “Direct-DC Power in Buildings: Identifying the Best Applications Today for Tomorrow’s Building Sector,” 2020 Summer Study on Energy Efficiency in Buildings.

KRISTIN LEWOTSKY is a freelance technology writer based in New Hampshire (chezhardy.com).

Follow our LinkedIn page for our latest news updates, contributed articles, and commentary, and our Facebook page for events announcements and more. You can also find us on Twitter.

Kristin Lewotsky

KRISTIN LEWOTSKY is a freelance technology writer based in New Hampshire (chezhardy.com). Lewotsky leverages her engineering background and deep experience in B2B media to brings technical concepts to varying levels of audience across fields such as microelectronics, semiconductors, optical and wireless communications, automation, and robotics.