Today, almost all illumination applications have been converted to LED light sources due to the significant advancements of that technology. Its use offers several advantages as for example high efficacy but also introduces some changes to conventional light sources: LEDs are smaller and emit less light flux compared to traditional solutions.

For high lumen applications two different approaches are feasible: The first one – with CoB (Chip on Board) LEDs – uses larger areas densely packed with an array of many small LED dies. The size of the light emitting surface is determined by the required luminous flux and the flux density of a single LED die. Diameters of such CoB LEDs reach up to 30 mm, with several hundred watts of power. This large light emitting diameter has implications on the size of the optics and the field of application. We have designed a non-glare optics of 350 mm diameter that collects and collimates the emission of such an LED "beast" and throws it efficiently over large distances, predestining it for the use in sport arenas.

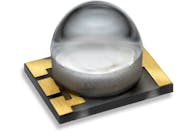

The second approach is the use of many distinct LEDs with individual optics. Here, the size of the optic is determined by the size of the single LED, typically in the range of a few millimeters. In the final application many sets of LED + optic are arranged in an array configuration. For easier system assembly the optics can be combined as a lens array (see picture).

Typical applications of lens arrays require luminous fluxes above 10000 lm with a highly defined light distribution of the luminaire. Optics can be small for use in consumer electronics (~10 mm) or larger for use in street lighting, flood lights for sport arenas or architectural areas.

What are the advantages of the latter approach? First of all, with smaller light sources many possibilities in terms of the light distribution can be realized. The application may be non-rotational with defined illuminance distributions, like a homogenously illuminated square on a floor or wall (wash effect), but also completely asymmetric lighting.

Due to the high power the application is challenging: in regards to thermal limits and subsequently to optical degradation glass is the material of choice. Our SUPRAX® borosilicate glass is ideal for high power applications and can be perfectly used for the production of lens arrays.

And what about your illumination task? Let's make your optical ideas work in glass. We will match quality and cost targets and you can lean back since from now on you don't have to worry about degradation and aging of your optics any more.