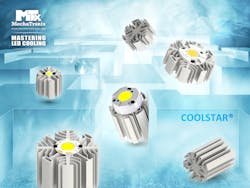

The CoolStar® family covers the whole range of cooling capacity from 1000 lumen all the way up to 6000 lumen, what positions them as well in the spot light developments as in the down light and shop light luminaires. The modularity in LED engines which can be mounted either directly or with a LED holder (ref. BJB, TE Connectivity, Bender Wirth) is respected on each design. On top of that some practical features have been added, like two closed wire pockets at the sides which allow to guide the wiring from the LED engine to the back side outside the visible field. Besides the black anodized versions which are commonly used, MechaTronix has also opted this time for a “pure white” electro-plating as an option, underlining the high-end looks and blending with the mostly white looks of both the LED engines and the LED holders.

Koen Vangorp “The biggest challenge was for sure to reach the uncompromised cooling performance the CoolStar® stands for without losing the looks we had in mind. It took us over six months and an endless amount of CDF thermal simulations to get to perfection. Certainly in the smallest diameters a very big step forward was made in cooling performance with a gain of over 35% compared to similar diameters on the market. Also this time we played on safe… patenting the whole series according the Hague System, which gives us design protection in all major parts of the world.”

The CoolStar® LED coolers will be presented at the Light + Building show in Frankfurt Germany, while global stock is under production to launch by end of February. MechaTronix is globally represented in 61 countries through 87 specialized distributors and has central warehouses in Taiwan, Hong Kong and The Netherlands.

For more information on the CoolStar® LED Coolers please contact MechaTronix on [email protected] or visit www.led-heatsink.com