How does cooling affect the lifetime of LED and Luminous flux? And how to judge cooling performance of lamps ?

About the cooling of lamp ,it seems that it is popular from the LED light source, why the led lamp pay attention to heat it ?the previous traditional light source is not talk about heat it.

Why does the traditional light source is not pay attention to cooling?

The earliest light source- Incandescent lamp, it is glow by heat it ,it does not matter as long as the temperature is not hot to melt the glass.

Halogen lamp is hotly ,but they don’t have any effect on the efficiency and lifetime ,as long as it does not hot to melt the components there is no problem.

Fluorescent light itself have little heat , but it also pay attention to “Insulation”, so so under normal circumstances do not pay attention to heat.

Metal halide lamp temperature is high, it is not need to pay much attention on the heat dissipation unless the power is high.

Why LED afraid of heat?

No matter how much the wattage of LED lamp, it need to do cooling, the reason “cooling” is because of its “fear of heat”. LED is a semiconductor device, when the temperature is higher, it will reduce the performance of led lifetime, and also may even end.

LED chip works with fever, we called it as junction temperature when it internal PN junction temperature.

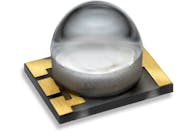

LED just work with a little chip, as you see from the picture.

What is the relationship of the junction temperature and Luminous flux of LED?

As you see from the picture , junction temperature is higher , Luminous flux is lower, when junction temperature is higher than LED working condition ,it will go down directly.

What is the relationship between junction temperature and LED lifetime? (when the general luminous flux down to 70%, we think that the LED end of life.)

As shown on it , the junction temperature of 105 degrees, the luminous flux dropped rapidly to 70%, then the LED lamp lifetime is about 10,000 hours, if the junction temperature is controlled to 55 degrees, the lifetime can be up to 100,000 + hours.

So, we must find a way to down junction temperature, so that the LED can dissipate heat of itself .

So how can we dissipate the heat?

LED cooling principle

We have learned at Middle school physics, there are three ways to dissipate heat: conduction, convection and radiation.

Conduction: The way the heat travels from the hotter part of the body to the cooler part of the body.

Factors affecting heat conduction:

1. The thermal conductivity of cooling material

2. The Thermal resistance of cooling structure

3, The size and shape of heat conduction material

Convection: the use of gas or liquid flow to take the heat away.

Radiation: the phenomenon of high-temperature objects dissipate the heat to outside directly .

Now there are two LED heat sink, almost the same shape, but one is sealed, the other is slotted, it is clear that the heat sink on the right is much better on heat dissipation, in addition to conducting heat dissipation there is a convection, and the left dissipate heat completely by conduction.

After you know the relationship between heat dissipation and luminous efficiency, life expectancy, and cooling methods, is there any way to determine the cooling of a lamp is good or not?

How to judge a LED light heat good or bad?

A lamp is designed with reasonable cooling and made fine, the cooling capacity and power have the relatively relationship . The size of the heat sink and the weight determines the heat storage capacity, so the heat sink is generally a big size. Heat sink area determines the final distribution capacity, in order to increase the area, it usually made into a variety of columns, net and other shapes.

The heat sink account a large piece of the cost of LED lamp, in order to save costs ,there be so many factories produced with lacking of materials and bad quality .So the question is :how can we judge a cooling of lighting is doing well ?

Of course ,the easy way is to measure the junction temperature of led clip when the light is working. As the junction temperature is controlled within an acceptable range, then the cooling is well done ,on the contrary is bad .

However ,it is not easy to measure the junction temperature, it requires a series of professional equipments and methods ,then can measure the led chip junction temperature inside the lamp .But some time even use the best equipments, we can just see the appearance from the outside ,not measure inside .

Using a professional imager ,you just can see the outside temperature, never know the led clip junction temperature inside .

Our designer or contractor can’t measure the junction temperature, when they chose the lights. The most easy way is to touch……then hot is well? Or not hot is well?

Firstly to clarify :it is not scientific to measure led lights temperature with hand touch, for different people feel different sensitive of temperature. However ,when the test equipment is not here ,you can roughly judge the lamp temperature by hand touch, for that the lamp temperature is lower than the temperature of scald hand .

Hand touch the heat sink is not hot ,not necessarily good

When LED lamp is working properly, a good cooling must be lower temperature ,but the lower temperature of cooling may not be good .

Why does a lower temperature heat sink is not necessarily a good one? The mainly problem is the conduction of heat, when the heat can’t be smoothly transmitted to the clip ,the heat accumulation around the heat source, by the high temperature heat transfer to the heat sink, so feel the temperature is not high.

Hand touch the heat sink is very hot, certainly not good

If your hand touch the heat sink is very hot, the cooling system must not be good, or the cooling capacity is insufficient; that the effective cooling area is not enough, making the heat can’t be quickly exchanged with the air, leading lamps dissipate the heat with the air by difference temperature, so feel very hot.

Some heat sinks looks very thick, in fact , “effective cooling area” is not enough. A cooling system, the part of which can access the air and the air can quickly leave the heat sink area ,is called “effective cooling area”. Other material that can’t be freely access to air ,at least ,only a heat capacity materials or heat radiation areas .

These are based on the physical measurement by hand, how to systematically identify the advantages and disadvantages of LED lamps cooling? Below information for you reference :

“Half-hour illumination method” test junction temperature

Since we can’t directly measure the junction temperature, is there an indirect way to get the junction temperature? Fortunately, the general LED junction temperature increases, the luminous flux will decline. Then, as long as we measure the illumination changes in the same position, we can know the change of junction temperature.

Do with this:

1 , choose a place from outside light, it is best to turn off the other lights at night.

2, turn on the lights cold, immediately measure the location of illumination, note the reading as “cold illumination.”

3, to maintain the lamp and the illumination at the same position, lamps continue to work.

4, half an hour later, then record it, write down the reading as “hot illumination.”

5, if the two reading are similar (10 ~ 15%), the lamp cooling system is basically good.

6, if the two reading are far apart (more than 20%), then this lamp cooling system is questionable.

The suitable rang of “ Half-hour illumination method ”

Let’s give several usual used chips “luminous flux vs. junction temperature”, you can see from this graph, the luminous flux decreased how much lumens, we can indirectly get the junction temperature rose to how many degrees Celsius.

Figure :Osram S5(3030) clip, the luminous flux than the 25 ℃ drop 20%,the junction temperature have reach above 120 ℃ .

Figure :Sensus series chip, the luminous flux than the 25 ℃ drop 15%, the junction temperature have reach above 105 ℃ .

As we can see from above figures, if half an hour after the hot illumination than the cold down 20%, basically the junction temperature has exceeded the chip tolerance range. Basically we can judge the cooling system is unqualified.

This is the most cases ,is there any special case? Of course :

Figure: OSLON Square 1-5W chip, junction temperature rise from 25 ℃ to 40 ℃, the flux is rise first then decline ,when it up to 120 ℃,the the luminous flux decreased by about 10% only. Therefore ,for the clip ,we use the “half hour illumination method” to measure heat ,only can accept 5-8% change.