Integrating sphere photometers and spectrometers simplify the testing of otherwise ‘difficult-to-measure’ light sources. Yet when measuring the total luminous or spectral flux of an LED or LED lighting system, one must consider the size, shape, spectral, and spatial light distribution to avoid testing errors.

One common testing error is called absorption error. Absorption is caused by items in the testing atmosphere, such as the metallic surface of a packaged LED, that absorb light differently than the reference lamp standard used to calibrate the integrating sphere photometer/spectrometer.

This can cause an accurately calibrated system to produce total luminous flux errors upwards of 15%. This can be avoided with the simple correction for absorption through the employment of an auxiliary lamp.

Introducing errors

Think of the integrating sphere photometer/spectrometer as one large detector. A reference lamp of luminous flux or total spectral flux is placed in the integrating sphere. The sphere is then calibrated to measure the flux of the lamp in the sphere. Now you replace the reference lamp with your test LED or lighting system and measure the total flux. Simple, right? Perhaps simple but possibly not accurate if an auxiliary lamp hasn’t been used.

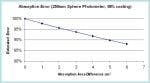

Let’s say, for example, your sphere photometer has a diameter of ten inches (250 mm) with a 98% diffuse reflectance coating. Let us also assume that your test LED and mounting hardware is roughly the same size as your calibration reference lamp standard.

The chart shows an example of the magnitude of error you could expect from different levels of devices and mounting hardware absorbance.

Correcting for absorption error

One option is to use a larger sphere; this reduces the ratio of the surface area of the LED and hardware to the total interior surface area of the sphere, making the absorption difference less significant. However, this is not always the most practical solution – large spheres are more expensive and can be difficult to accomodate in a laboratory.

A better option is to stay with the appropriate sphere diameter and equip it with an auxiliary lamp to allow for the measurement of self-absorption by the reference lamp, the devices under test, and the associated hardware.

The auxiliary lamp should be located in the sphere where it can illuminate the sphere wall yet remain shielded from the photometer/spectrometer and the device under test. It should also be stable against shock. A simple relative measurement of the auxiliary lamp with the reference lamp in the sphere, and again with the test LED, can help you correct and avoid absorption errors associated with LED spectral measurements.

While this explanation sounds simple in actuality modeling absorption errors is extremely complicated. Factors such as the diameter of the integrating sphere, the spectral reflectance and diffusivity of the sphere wall coating, the location and size of the baffles and mounting hardware, the spatial uniformity of the sphere, the spatial distribution of the source, and more, can contribute to the uncertainty of measurement results.

It is important, and good laboratory practice, to recognize these factors and know how they can affect your measurement results. It is also important to have knowledgeable support when using a testing system for your application so potential issues are identified and dealt with.