Seoul Semiconductor adds to high-power LED family, boosts efficacy

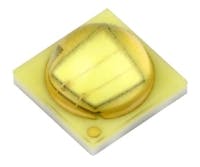

Seoul Semiconductor has added to its Z5-M series of high-power packaged LEDs with the Z5-M1 family that is optimized for high efficacy. Solid-state lighting (SSL) manufacturers can choose models across the 2600K to 7000K CCT range and operate the LEDs at power levels to 5W.

Most of Seoul's announcements of late have been focused on its mid-power LEDs and the Acrich2 AC-based LED driver IC. But even the LEDs used in AC-LED light engines are standard DC LEDs and the improved high-power components make Seoul more competitive in the broad LED market sector.

While higher evolutionary efficacy is a recurring theme in the LED arena, Seoul explicitly said that the new LED design targeted an efficacy boost. "The efficacy enhancements in the new Z5-M1 series not only ensure a reduction in luminaire development costs incurred by our customers, but also enable the best possible color over angle homogeneity with the new phosphor coating technology," said J.B. Choi, president of the Lighting Division for Seoul Semiconductor.

A 3000K, 80-CRI warm white LED driven at 350 mA and operated at an 85°C junction temperature yields 132 lm/W. A 6000K, 70-CRI cool white LED driven at 350 mA and operated at an 85°C junction temperature yields 150 lm/W.

Seoul said that both advancements in the chip architecture and the phosphor technology enabled the efficacy gain. A prior generation Z5-M0 3000K LED delivered efficacy in th3 116 lm/W range. Seoul didn't specify the types of chip enhancement it implemented, but techniques such as patterned substrates are regularly used today to maximize light extraction.

The new LEDs can be operated over a broad range of drive currents, allowing SSL product developers to trade off the number of LEDs used in a design with efficacy and rated life. For example, a 3000K LED can deliver 117 lm at 350 mA, 210 lm at 700 mA, and 322 lm at 1.2A, all driven at 350 mA and operated at 85°C. But efficacy drops to the 85 lm/W range at 1.2 A. Still using fewer LEDs to deliver a specific lumen package in an SSL product can significantly reduce the bill of materials (BOM) cost.

And while this recent announcement was focused on high-power LEDs, most likely for use in a DC-based light engine, Seoul also presented a webcast recently on AC-LED technology. If you want to learn more about that topic that is growing in popularity, presenter Dave Neal used his application engineering experience to deliver an unbiased and comprehensive view of the AC-LED landscape.