Four ways to die: Overcoming common challenges in SSL design (MAGAZINE)

NAT CANNON details common causes of LED failure in solid-state lighting systems, and offers guidance on avoiding the potential pitfalls and delivering reliable products.

Simultaneous with the rapid advancement of LED component technology over the last several years, a second revolution has also been taking place in solid-state lighting (SSL) luminaire and system design. In the early days of SSL design, we would frequently see obvious engineering mistakes and Frankenstein-looking retrofit lamps and luminaires come into our Durham, Santa Barbara, Hong Kong, Shenzhen, and Shanghai Applications Tech Centers with their creators looking for engineering design help and advice. We still see some of those on occasion, but most of the design errors we have seen in recent history are of a more subtle nature. While these mistakes may be less obvious, they can be just as limiting to the market potential of the individual designs — and detrimental to the reputation of the offering company and the proliferation of SSL as a whole.

Since it was launched in the fall of 2011, Cree Services has tested more than 500 luminaires and retrofit lamps in our Thermal, Electrical, Mechanical, Photometric, Optical (TEMPO) test program. The TEMPO testing program has provided a unique window to observe the rapid acceleration of SSL luminaire design capability and creativity in the industry. That said, there are still a few common mistakes we see even the most experienced SSL designers make. This article discusses the top four design mistakes we see most frequently, and makes some helpful suggestions to avoid them and bring quality SSL luminaires to the market.

Electrical overstress

Our first area of focus is the electrical environment. Electrical overstress (EOS), exposure of a component to current or voltage beyond its maximum specifications, is the leading cause of LED failures, regardless of the manufacturer. LED EOS failures result from excessive localized heat generated by the high current or voltage transient that causes damage to the materials in the LED. Like all semiconductor devices, LEDs have a limited ability to survive overstress.

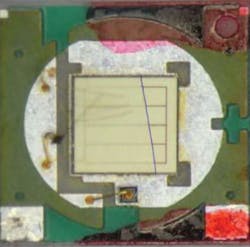

Cree recently conducted a rigorous regime of testing of three general categories of LEDs: mid-power single- and multiple-chip LEDs, high-power single-chip LEDs, and high-power chip-on-board (COB) LEDs from multiple LED manufacturers. The test consisted of applying square-wave pulses of power levels up to 1700W, with time durations ranging from 0.1 to 70 msec (milliseconds), to each LED to simulate real-world EOS conditions. The failure criteria were based on junction leakage current measurements performed after each pulse. If the leakage current exceeded the device specifications, the result was considered a failure. Fig. 1 shows an example EOS failure of a high-power LED.

In general, single-chip high-power LEDs with multiple contact vias are most robust against EOS events. Low-power plastic packages are most susceptible to damage from EOS events. COB LEDs with more parallel strings of chips are more robust than COB LEDs with fewer parallel strings. Larger LEDs are more robust than smaller LEDs. For all the tested parts, as the power-to-failure increases, the time-to-failure decreases.

Events ranging from lightning strikes to driver in-rush current at power on can subject LEDs to a variety of EOS events. However, failure-inducing EOS events can be avoided by applying proper protection techniques, including metal-oxide varistors (MOV) for over-voltage protection and positive temperature coefficient (PTC) resistors for over-current protection. The general guideline is to design a protection circuit capable of preventing anything greater than a 0.1-msec spike of 2–3 times the maximum rated current of the LED from reaching the LED. A more detailed discussion of this topic can be accessed at www.cree.com/xlamp_app_notes.

Thermal management

Next up, thermal issues can lead to premature LED failure. LEDs are designed to perform over a range of operating temperatures. With all LEDs, the expected lifetime depends on the operating temperature. One of the most critical design parameters for an LED illumination system is the system's ability to draw heat away from the LED junction.

High operating temperatures at the LED junction adversely affect the performance of LEDs, resulting in decreased light output and lifetime. Properly managing this heat is the result of attention to thermal management in the design, assembly, and operation of LEDs in lighting applications. Insufficient thermal management can result in damage very similar in appearance to that caused by chemical incompatibility — a topic we will address shortly; however, unlike chemical incompatibility damage, thermal damage is irreversible.

LEDs are commonly soldered to an FR-4 or metal-core printed-circuit board (MCPCB) that is attached to a heat sink. FR-4 boards are less expensive than MC-PCBs but have higher thermal resistance. COB LEDs are commonly attached to a heat sink using a connector that attaches to the heat sink with screws. A good thermal connection between the COB LED and the heat sink is critical for successful designs. A thermal interface material (TIM) is required for optimal performance. Air is a thermal insulator, so a TIM is needed to fill any voids between the COB LED and the heat sink. Without a TIM, there are a limited number of spots for heat transfer from the LED to the heat sink to occur. With the voids filled by a TIM, heat flows much more freely from an LED to the heat sink. In any case, careful consideration must be taken to ensure a sufficient thermal path to ambient is provided. Fig. 2 shows an example of significant temperature variation — 22°C — in a luminaire due to inconsistent application of the TIM to the heat sink.

Chemical compatibility

Now let's discuss chemical compatibility. The presence of incompatible volatile organic compounds (VOCs) in LED-based system designs can impair the performance and reduce the lifetime of these illumination systems. Glues, conformal coatings, O-rings, gaskets, and potting compounds are materials frequently used in the construction of LED-based luminaires or lamps, and often contain VOCs. The presence of chemically incompatible VOCs on or near LEDs can degrade the light output levels or cause changes in the chromaticity point of the light. The photograph in Fig. 3 is an example of this VOC degradation on the surface of an LED.

This sensitivity to VOCs is not unique to one LED manufacturer but is a known problem for all types of blue, royal blue, and white-light LEDs. We typically do not see these issues with green, amber, or red LEDs due to the longer, lower energy level of these wavelengths.

Chemical incompatibility in SSL systems is often a localized phenomenon, occurring in luminaire designs that seal portions of the system, resulting in an LED operating environment having elevated temperatures with little or no air movement. However, with proper design and adequate testing, chemical incompatibility effects are preventable. (For more information on chemical compatibility and a table of known "good" and "bad" chemicals, see www.cree.com/xlamp_app_notes/chemical_compatibility.)

LED handling and manufacturing

LED handling during the SSL system manufacturing process is the fourth most common area we see that can lead to product failure. Handling problems in general span a broad set of potential failure modes and here we will focus on some specific sub-categories. We will discuss four of the most common: moisture ingress, PCB flexure, soldering and solder coverage, and component pick-and-place.

Moisture ingress. Many LEDs, particularly those constructed from plastic, are susceptible to damage from moisture ingress. Most LEDs are shipped in sealed moisture-barrier bags (MBBs) and are designed for long shelf life if the MBB remains unopened. If moisture-sensitive LEDs are exposed to high-humidity environments after opening the MBB packaging but before soldering as shown in Fig. 4, damage to the LED may occur during the soldering operation.

LEDs that are exposed to moist environments in excess of the manufacturer's maximum exposure limits will require pre-conditioning, often baking for a period of time, prior to soldering. Baking of LEDs for the recommended temperature and time will remove any moisture and reset the exposure time as defined by the manufacturer.

LEDs that have not been soldered but that are unsealed or removed from the original packaging should be properly stored to prevent excess moisture ingress. Below are some common storage practices used within the industry:

• Store opened LEDs in a rigid, airtight container with fresh desiccant and a relative humidity (RH) indicator.

• Store parts in a dry, nitrogen-purged cabinet or container that actively maintains the RH below the exposure limit.

• For short-term storage, LEDs may be resealed in the original MBB soon after opening. Fresh desiccant and a humidity exposure indicator should be placed in the MBB to monitor exposure levels.

PCB flexure. PCB bending and/or flexing is an unavoidable phenomenon that is known to exist and is easily encountered during the electronic board assembly processes. PCB bending and/or flexing is the fundamental source of tensile stress induced on the electronic components on the board assembly. For more brittle components, like ceramic-based LED components, micro-cracks can be induced and eventually lead to failure (Fig. 5).

Following are situations in which a PCB can bend or flex, resulting in cracks in an LED chip attached to it:

• Screw tightening/torqueing.

• Uneven/convex PCB surface.

• Reflow soldering the LED board.

• PCB punching/separation.

Cracks in the LED chip and substrate resulting from PCB flexure have been identified to cause unstable, partial, or no-emission LED failures in ceramic substrate-based LEDS. This damage can be minimized or avoided by practicing the following:

• Do not overtighten the screws when attaching an LED board to a heat sink. Automated torqueing and the tightening of screws with a set torque force are recommended.

• Do not use an excessive amount of thermal grease or a thick thermal tape/pad.

• Do not use partial application of thermal grease or tape under the LED component only. An even spread and controlled volume are critical to minimize possible board bending/flexing during the fastening process.

• Do not mount an LED board on a warped, convex, or uneven surface.

• Do not use an excessive amount of solder to attach an LED to a PCB.

When handling or separating LED boards after assembly, always ensure that the boards are properly supported to minimize board bending and flexing.

Soldering and solder coverage. To properly manage heat, specific practices should be followed in the design, assembly, and operation of LEDs in lighting applications. Insufficient solder attach between the LED and PCB and poor thermal transfer between the PCB and heat sink are common causes of LED failure. In Fig. 6 we see an LED mounted on a PCB with severe solder voiding. While this failure presents itself as a thermal problem (high solder point temperature), the actual root cause lies in the manufacturing process, not in thermal design.

Most lighting-class LEDs are designed to be reflow soldered to a PCB. Reflow soldering may be done by a reflow oven or by placing the PCB on a hotplate and following the manufacturer's reflow soldering profile. The choice of solder and the application method will dictate the specific amount of solder. For the most consistent results, an automated dispensing system or a solder stencil printer is recommended.

When establishing a soldering process, adjusting an existing process or qualifying a new product, it is recommended that the consistency and quality of the solder bond be verified on several trial PCBs prior to running good product. The easiest and quickest method to verify the solder bond is with an x-ray inspection. If x-ray analysis is not available, shearing and inspecting the LEDs is also an acceptable method. Adjustments should be made if un-reflowed solder or excessive voiding is observed during inspection.

Component pick-and-place. Pick-and-place is an automated operation in which a robotic arm retrieves a component such as an LED from a dispensing mechanism and places the component precisely on a PCB. Manufacturers not familiar with the specific pick-and-place requirements of LEDs often experience low pick-and-place yields or cause physical damage to the LEDs, as shown in Fig. 7. The inclusion of LEDs in the pick-and-place process introduces many variables that can affect the performance of the pick-and-place system; most automated pick-and-place tools were designed to work at high speeds with flat-top semiconductor components, not domed-top LEDs. LEDs require specific process parameters for the pick-and-place equipment to optimize the system's performance. The pick-and-place issues faced with LEDs are primarily due to the physical differences in traditional surface-mount devices (SMDs) such as integrated circuits (ICs) and SMD LEDs.

Advances have been made in recent years to overcome these common pick-and-place issues encountered with LEDs. Most issues can be addressed by making simple tooling adjustments, selecting the proper nozzle for the LEDs being used or by using a feeder unit optimized for picking and placing LEDs. For more information on pick-and-place operation, see www.cree.com/xlamp_app_notes.

While great strides have been made over recent years in SSL luminaire design, we still see more subtle issues with a number of fixtures from our TEMPO testing. Electrical overstress, thermal design, chemical compatibility, and handling and manufacturing issues are now the most common sources of poor performance in LED systems. You can avoid problems related to these issues by carefully following the design guidance provided by LED manufacturers such as Cree.

NAT CANNON is an applications engineer at Cree, Inc.