GUV SYSTEMS | Rethinking wall plug efficiency for UV-C LEDs in water disinfection

Advances in ultraviolet C-band (UV-C) LED performance have accelerated in the past five years. Coupled with the COVID-19 pandemic and awareness around touchless disinfection, activity in the germicidal UV space has led to more comparisons between UV-C LEDs and mercury lamps. One recent debate has been on the wall plug efficiency (WPE) of UV-C LEDs compared to legacy disinfection technology. WPE is the ability of a device to convert energy into light. Some industry stakeholders have proposed that UV-C LED adoption in germicidal UV (GUV) applications will be limited until the devices can match the performance of existing commercial mercury lamps.

Doubt around readiness of UV-C LEDs for widespread adoption has previously been debated with respect to power and lifetime. But as more OEMs evaluate the technology and lean into its inherent benefits around design flexibility and on-demand operation, market leaders can see that the technology is in fact ready, especially for low-flow water disinfection applications. Intelligent designs that optimize the placement of LEDs, water flow, and duty cycle parameters have driven commercially available UV-C LED–based disinfection reactors that exceed performance requirements.

Why is there debate around WPE? Simply stated, the WPE of UV-C LEDs is still relatively low — between 3% and 10%. In fact, most of the energy applied to the device is still converted into heat. However, just as with power and lifetime, performing apples-to-apples comparisons between WPE of UV lamps and UV-C LEDs still doesn’t make sense. Although it is an important metric, WPE is not the sole measure of progress for this technology.

Materials influence WPE

Current WPE of UV-C LEDs is in the single digits, with most commercially available UV-C LEDs in the range of 3% to 6% depending on the product. Improved LED efficiency can be achieved at multiple points within the device, commonly categorized as either internal or external efficiency. Internal efficiencies can be improved by reducing defects and dislocations in the epilayers of the substrate material. External efficiency can be improved by redesigning the device for better light extraction.

Many UV-C LED manufacturers grow structures on bulk sapphire, a low-cost, transparent substrate. However, sapphire has lattice and thermal expansion mismatch with the nitride layers, creating an increased number of dislocations in the material, which fundamentally limits the internal efficiency for sapphire-based UV-C devices. Manufacturers using bulk sapphire as a foundation focus on improving extraction efficiency to improve the overall WPE for their devices.

Manufacturers that use bulk aluminum nitride (AlN) substrates have an inherent internal efficiency advantage — more specifically, the internal quantum efficiency (IQE), which is the percentage of electron-hole recombination that results in a photon as opposed to the heat that is generated when an electron encounters a dislocation defect. Devices grown on AlN have demonstrated more than double the IQE at UV-C wavelengths compared to those grown on sapphire substrates. Thus, manufacturers using bulk AlN as the foundation for their UV-C LEDs seek to improve WPE through improved internal and extraction efficiency.

Adoption increases despite current WPE

Over the past few years, adoption has increased for UV-C LED–based technology in point-of-use (POU) water systems that operate at flow rates of up to 5 gallons per minute. Point-of-entry (POE) systems are generally defined as having a flow rate of 5 to 50 gallons per minute (gpm), and we are seeing adoption of UV-C LEDs in the lower-flow systems. Industrial, wastewater, and municipal treatment is traditionally defined as flows of more than 50 gpm. POU and POE systems will typically operate at a low duty cycle, whereas the high-flow systems have more continuous operation.

WPE and duty cycle go hand in hand. The low duty cycle in POU and POE means that a WPE between 3% and 6% is more than adequate. Higher WPE is favored for higher flow rates to reduce heat load, because these systems demand more LEDs to reach appropriate disinfection dosage requirements.

In general, most OEMs considering UV-C LED–based product development go beyond a mere light source swap from lamp to LED. They often redesign applications to take full advantage of the LED benefits such as smaller footprint, instant on/off, and wavelength effectiveness. As they design such disinfection products, they can optimize system operation so the WPE parameter becomes less important with regard to energy consumption.

Impact of WPE in a POU water disinfection system

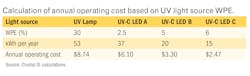

We can use a residential POU water disinfection system design for WPE and operating cost comparisons. The impact on total cost of ownership is a common benefit for consumer POU applications, as LEDs operate only while disinfecting. Mercury lamp–based systems will operate with an idle mode or lamp cycling to reduce the impact of lamp warm-up time on the user.

A system using a 11W lamp may consume only 5.5W while in idle mode. It would potentially operate at full power 10% of the time and in idle mode the other 90% of the time. At this rate, the system would draw a little over 53 kWh per year from the building electrical supply. According to the U.S. Department of Labor, as of May 2023, the average electricity kWh cost in the U.S. is $0.165, bringing the operating cost to just under $9 for a typical year.

If we consider the same system performance with an LED-based design, we can evaluate the annual energy cost for a few different LEDs with varied WPEs (see the nearby table). Although we can assume the same operating time — 10% on/90% idle — typically when an LED-based system is at idle, there is no power draw from the light source.

Switching from a lamp-based system to the UV-C system saves the end user anywhere from 30% to 70% on energy costs depending on the UV-C LED employed. However, an improvement from 5% to 6% WPE provides less than $1 in annual savings. While the switch from lamp to LED is compelling when paired with the other sustainability advantages, the impact of a discrete LED’s WPE on the end consumer is negligible — particularly at the current range of WPE across commercially available UV-C LEDs. For the lower-flow POE market in the 5 to 12 gpm range, a 5% WPE seems to be the threshold for broader market adoption.

Design discussions concerning WPE often center around reducing the number of LEDs and decreasing heat load to lower overall system cost for the OEM. This becomes less about the WPE and more about the efficiency of the disinfection power employed, which is the impact of the total UV-C power on the target microbe at the target wavelength.

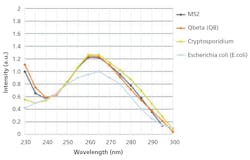

Disinfection systems must meet a particular disinfection performance based on a target microbe or biodosimer being used to develop the GUV system and that biodosimer’s spectral response. The biodosimer is a surrogate test microbe used to ensure the system delivers the claimed disinfection performance for the intended application. These microbes are often defined by industry standards organizations such as the National Science Foundation (NSF) or Environmental Protection Agency in the U.S. However, some manufacturers may prefer to use a specific microbe based on other regional market requirements. For example, the NSF defines Qbeta as the target microbe for systems seeking certification, while an OEM targeting the European market would design with Pseudomonas A.

Referring back to the table, since UV-C LEDs B and C have very close WPEs, we can then compare the disinfection performance and cost for two system designs using these LEDs. LED B with the 5% WPE offers power output of 160mW at 265nm (a commonly used UV-C disinfection wavelength), while LED C with a 6% WPE emits 140mW at 275nm. A system targeting E. coli bacteria would require 20% more power in the LED C package to meet the same disinfection performance as the system using LED B. Although there may be a benefit in WPE and the annual operating cost to the end user, when looking at the LED budget in the overall system, LED B becomes the more attractive option.

Considerations for scaling to large-flow, continuous disinfection

In the current addressable applications around point-of-use, point-of-dispense, and lower-flow POE applications, existing commercial UV-C LED performance meets OEM requirements — including the WPE performance. There is some early adoption in the industrial water treatment sector, particularly in beverage and pharmaceutical processing and dispensing equipment that operates intermittently. These industries are looking to take advantage of other key LED benefits, such as reducing unplanned maintenance that will offset an increase in system cost.

As we look at higher-flow use cases in municipal and wastewater applications, WPE is likely to become more important. Legacy large-scale systems use massive lamps that consume a great deal of energy — thus energy efficiency may hold more weight than other parameters when developing such systems.

The industry is just beginning to see UV-C LED–based equipment for these applications and already early adopters are reimagining what a typical reactor design looks like. For example, new LED systems are employing external cooling methods, as opposed to process water like legacy systems. Leaders in this space will continue to challenge conventional wastewater and municipal reactor designs to leverage UV-C LEDs, just like POU and POE OEMs are doing today, scaling them to even greater benefit as the system deployments serve a larger population.

EOIN CONNOLLY is president and CEO, and RAJUL RANDIVE is director of global application engineering at Crystal IS, a UV-C LED developer based in Green Island, New York.

Follow our LinkedIn page for our latest news updates, contributed articles, and commentary, and our Facebook page for events announcements and more. You can also find us on the X platform.

Rajul Randive

Eoin Connolly

EOIN CONNOLLY is president and CEO of Crystal IS, a developer of UV-C LEDs for OEMs based in Green Island, New York. Connolly has more than 20 years of experience in engineering, business development, product marketing, strategy, and corporate management roles. Prior to his time with Crystal IS, he worked with several GE businesses, as well as Siemens PTI and Plug Power. Connolly joined Crystal IS in 2016, rising from vice president of product management to president and CEO. He has a BSc in mechanical engineering from University of Dublin, and an MBA in entrepreneurship and technology from Rensselaer Polytechnic Institute.

![The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.] The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.]](https://img.ledsmagazine.com/files/base/ebm/leds/image/2024/08/66be810888ae93f656446f61-dreamstime_m_265700653.png?auto=format,compress&fit=&q=45&h=139&height=139&w=250&width=250)