Cree delivers high-power LED optimized for low system manufacturing costs

The MH-B LED is designed for lighting manufacturers that are using automated surface-mount-capable production lines, and offers high-power performance with mid-power looks.

Cree has announced the XLamp MH-B family of high-power LEDs that were designed specifically as an alternative to mid-power devices with the goal of minimizing the system and manufacturing cost of solid-state lighting (SSL) products. The 6W surface-mount device (SMD) delivers 830 lm and will be sold over the range of 2700K–6500K CCTs.

Mid-power LEDs are increasingly popular in some lighting applications with performance sliding to the high-power sector. For example, Seoul Semiconductor recently added high-voltage versions of mid-power LEDs. Moreover, manufacturers such as Samsung plan to further reduce the cost of mid-power LEDs. Still, it remains to be seen if mid-power LEDs can win in demanding applications such as downlights, street lights, and high-bay luminaires.

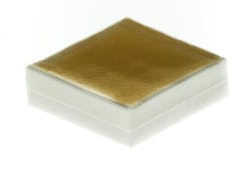

The Cree 5×5-mm MH-B family looks much like mid-power LEDs that are on the market, although the performance specs are at the upper end of the high-power range. Still, the LED can be handled and installed with surface-mount manufacturing equipment much like typical mid-power LEDs. Indeed, automated surface-mount assembly is a requisite for many SSL products that use mid-power LEDs because the lower output of mid-power devices results in many such LEDs being used in a product. The new Cree product will offer manufacturers the needed SMD compatibility along with the ability to use far fewer LEDs in the system.

The new Cree product family attacks both the system and manufacturing cost issues. Paul Scheidt, head of product marketing for LED components at Cree, provided a detailed look at the typical bill of materials (BOM) of an LED lighting product. Today, the LEDs comprise about 30% of the BOM cost. Meanwhile, the combination of thermal management, optics, and printed-circuit board (PCB) costs totals around 45% of the BOM. Scheidt said that some lighting manufacturers move to mid-power LEDs to try and minimize LED component cost, but that choice could result in higher system costs because the optics, thermal, and PCB costs are more easily attacked.

Scheidt used several examples to make the system-cost point. He said that a 1200-lm downlight needs only three of the new MH-B LEDs, whereas such a product would require upwards of 40 5630-type mid-power LEDs. While it seems logical that the fewer LEDs would enable simpler manufacturing, the automated SMD lines take the cost out of the manufacturing process to some extent.

Still, there are other impacts. For example, Scheidt said the PCB cost would be around $3.70 for the mid-power example based on the size of the PCB required to host the number of LEDs. The PCB for the MH-B LEDs would cost pennies, according to Scheidt, and even the cost of pick-and-place on the manufacturing line would be lower for the fewer high-power LEDs. Scheidt also said the mid-power design would require larger and more-expensive optics and heat sinks.

Of course, Cree also believes that the high-power option equates to a higher-quality product as well. "Mid-power LEDs get to a low cost, especially for manufacturers who have invested in surface-mount assembly," said Scheidt. But he quickly pointed out that problems in color consistency and lumen maintenance continue to plague mid-power designs.

For a lighting manufacturer to deliver tight color uniformity at the system level using mid-power LEDs, the manufacturer must typically mix LEDs across a number of bins, creating additional manufacturing complexity and cost. Cree will offer the MH-B family optionally within a two-step MacAdam ellipse. Cree can deliver such consistency because the MH-B actually is implemented as an array of emitters and Cree delivers the correct mix using what the company has always called EasyWhite technology.

Moreover, Scheidt said even mid-power LEDs with enhanced packages still lack the thermal capability of high-power devices. He said the lighting manufacturers can design products with the expectation that junction temperature hits 105°C, and that MH-B designs would match the lumen maintenance of the best mid-power LEDs operated at 85°C.

While some products such as linear fixtures spread mid-power LEDs over relatively large areas and eliminate thermal issues, applications such as a downlight or high-bay fixtures will locate the LEDs in tight spaces and in a sealed environment. Scheidt said that mid-power designs will need larger heat sinks to match the system-level reliability achieved with high-power LEDs.

The combination of SMD compatibility and high-power performance won praise from one lighting vendor. "While chip-on-board LEDs are an attractive alternative to mid-power LEDs in terms of reliability and cost, they aren’t compatible with my automated manufacturing processes," said Frank Chen, technical director, Zhejiang Shenghui Lighting Co. "The new XLamp MH-B LED finally gives me a more reliable alternative to mid-power LEDs – I no longer have to compromise my brand and reputation to achieve a lower system cost."

The new LEDs are at launch a high-voltage design. The forward voltage specification of 37V would suggest that there are 10–12 emitters connected in series in the package. The phosphor is applied in the packaging process. And as you can see, there are no primary optics just as is the case with most mid-power LEDs. Scheidt said Cree may offer more electrical configurations, but increasingly we have seen the high-voltage LEDs are popular in terms of reducing driver complexity.

Cree presented a prototypical retrofit lamp design that might use the new LED. The AC-line-powered GU10 flavor of an MR16 lamp needs only one of the LEDs to deliver 423 lm, and center beam candle power (CBCP) of 2998 cd. Cree said that performance is equivalent to a 35W Energy-Star-rated halogen lamp. The lamp efficacy is 65 lm/W. Clearly, the LED in the prototype is not driven at the 175-mA maximum in a typical design that must balance lumen output with efficacy and temperature.

Maury Wright | Editor in Chief

Maury Wright is an electronics engineer turned technology journalist, who has focused specifically on the LED & Lighting industry for the past decade. Wright first wrote for LEDs Magazine as a contractor in 2010, and took over as Editor-in-Chief in 2012. He has broad experience in technology areas ranging from microprocessors to digital media to wireless networks that he gained over 30 years in the trade press. Wright has experience running global editorial operations, such as during his tenure as worldwide editorial director of EDN Magazine, and has been instrumental in launching publication websites going back to the earliest days of the Internet. Wright has won numerous industry awards, including multiple ASBPE national awards for B2B journalism excellence, and has received finalist recognition for LEDs Magazine in the FOLIO Eddie Awards. He received a BS in electrical engineering from Auburn University.