ESCO model makes sense in retrofitting SSL for smart building services (MAGAZINE)

Leveraging the expertise of an energy service company can help building operators move their facilities into an intelligent future with reasonable expense management, writes LIONEL BARDEN.

The world is changing dramatically with huge technological advances for smart buildings and sustainability of the building operation. These changes are capable of massive disruption to the standard operational process - but only if they are taken up. Where do the current building owners and operators of established buildings stand on this complex business-planning decision? If they decide not to change with the times, they risk missing the many opportunities the technology provides. More to the point, they risk the fact that their opposition could gain a huge advantage by being first to adopt LED-based smart building technologies.

Interested in articles & announcements on smart buildings & lighting?

The benefits of an ESCO

An energy services company (ESCO) is a multifunctional energy service provider that provides the technology of mechanical and electrical services to an existing or new building project for the estimated life of the building (15-25 years) for a simple periodic service fee. Rather than a traditional model of multiple, individual subcontractors, the fully funded design, supply, installation, and maintenance is under one banner in the ESCO model providing the total service (Fig. 1).

All of the equipment is fully maintained and upgraded at the time of either the end of serviceable life or a major technology improvement. This provides the building owner/operator (BOO) with the very latest technology and future proofing of the systems over the life of the building. In new installations, these technological changes provide huge savings for the developer in the adoption of the electrical/mechanical cost incorporated in a service fee through the operational expenses (opex), which experienced ESCOs guarantee is less than the traditional tendering system of capital expenses (capex) and the residual opex.

FIG. 1. The lighting as a service (LaaS) provider takes responsibility for the entire smart building retrofit project.

The responsibilities of choosing equipment through to contracting experienced installers and maintenance people and finally funding the project reside with the ESCO and their experience in the technology. In this article, we will focus on the introduction of lighting as a service (LaaS) of established facilities that operate day to day and many on a 24/7 basis. The LaaS provides monitored control delivered through a solid-state lighting (SSL) system for energy reduction and intelligent upgrading to smart building status.

Funding the project

The total service is provided without capex. The opex, which includes the material and installation costs, is calculated to be less than the current or traditional opex and there are no further costs other than a single periodic service fee and the new dramatically reduced electricity bill (Figs. 2 and 3).

Let us look at the current and standard processes. These include:

• Carrying out an audit of current energy used and the source

• Designing into the project the replacement equipment

• Sourcing this equipment

• Contracting the electrical installation

• Contracting the maintenance company

The audit and the design are carried out by independent contractors. The general focus of the audit is to establish the actual energy used and possible reduction methods mostly without actual equipment focus.

The lighting design, normally following a budget, provides the replacement system from cataloged and/or specified equipment. Once the design is complete, the equipment is tendered for supply. At this stage the auditor has finished their responsibility. Oftentimes the designer has little say in the final choice of equipment, which, in almost every case, is selected with a major emphasis on price to fit the project management budget. This is usually carried out by another influential independent, the purchasing or sourcing manager.

Again, the installation contract is tendered and even though this may be to a selected group, price leads the consideration. The selected contractor follows standard installation procedures with little knowledge of the new equipment. When the maintenance provider is finally selected either by tender or by using current contracted staff, the detail of that maintenance will be learned on the job.

There is no interface between these specialists. In the selection of traditional equipment that has been around for many, many years, this process is satisfactory but with the introduction of new technology the end result can be fraught with danger.

With retrofit installations, one has to deal not only with the technological changes but consider other major influences, such as equipment design for retrofit replication per project; speed of installation; disruption to trade or operation; daily window of timing for installation; monitor and control connection platform; and the correct removal, destruction, or recycling of replaced equipment.

Most of the time there is no funding - or never enough - for the retrofit or replacement of the technological changes, including the control system. The upfront cost of quality replacement equipment is very high and there is hesitation in the market for customers to proceed because of cost, trust, and warranty (see Strategies in Light Europe keynote comments addressing this issue). If the project is funded upfront, the payback period can take as long as 2-3 years, during which time the warranty expires and the risk of replacement resides with the BOO. Warranties are mostly on equipment only and do not include installation and commissioning.

FIG. 2. The chart compares original monthly operational costs of a building with its new costs at current prices after a smart building retrofit through the ESCO model. Cost savings shown are from one month following the retrofit.

This places enormous responsibility on the BOO, who may decide the risk is too great and loses out on the technological gain. By choosing a LaaS model, the BOO mitigates the risk of maintenance and replacement altogether.

Getting an audit

The equipment manufacturing, supply, and installation methodology should be based on the outcomes of a comprehensive audit. While it should include the detail of the current electrical operating systems and the opportunities to reduce the demand, it should also include onsite inspection; collation of electrical, air conditioning, sprinkler, and lighting plans; and diagnosis of installation difficulties and obstacles.

The audit should also provide the ability to complete a multiple-site project within the shortest possible time, focusing on the daily business activity through to employee, contractor, and customer attendance timing and traffic movement. It is essential that the total package is designed to eliminate any disruption to normal operational activity or trade.

The BOO cannot close an active service or business to install new systems because of the loss of that service or trade, be it a hospital or a supermarket as examples.

To be able to supply this information correctly from multiple sites, a standard compilation of information should be provided from each site. The equipment selection, on-site timing, and methods of installation should be designed to be the same at all locations.

Equipment selection

The equipment chosen should be from manufacturers with respected brands, irrespective of price. These brands should guarantee the highest quality and the latest technology, while substantiating a long life and low maintenance with strong warranties.

FIG. 3. Seen here is a detailed cost comparison of actual ESCO retrofit cost calculations for the first year set alongside estimated cost growth over 5 years (with no increase in service fees).

The equipment - while standard in the new technology format - should be custom designed to suit each project. Every project is assessed and equipment is modified if necessary for that specific installation. Apart from an overall continuity of quality, the design should be an empathetic replication of the original performance and effect. The equipment should be designed specifically around speed of installation (see an example in Fig. 4). Therefore, it is important to have the manufacturers included in the project planning.

Project management

It is important that the same project manager is charged with overseeing the audit and is therefore familiar with the layout of each facility. There is only a small window of opportunity for the installation, so it is important that the project manager train and direct the installation crew through a "train the trainer" program in understanding the technology, as well as handling and installing the equipment correctly to complete the installation to prescribed documented processes and within allotted operational periods allowed.

FIG. 4. The SSL equipment with monitoring and controls used in this supermarket project was retrofitted in 2.5 min per fitting as a result of the appropriate selection and customization of the specified products.

The project manager should also be responsible for selection and training of the maintenance crew, which should contain members of the installation crew who have knowledge of the technology as well as handling and installing the equipment correctly.

Monitoring a smart building

An intelligent monitor system (IMS) is the most important part of a smart building package because of its ability to provide further saving on current costs and feedback on operational ergonomics and logistics.

One must be careful when selecting the platform for a monitoring system because data-cabled systems are now common with new installations but are basically impossible to use in retrofit situations because of the time/cost of installation and physical barriers. However, many companies or organizations will not allow the use of Wi-Fi either integrated into or in tandem with their current Wi-Fi system. Thus it is important to investigate other platforms acceptable to the project. The established system should alert of individual equipment failure back to a dashboard; identify the facility and individual location of the equipment; monitor the electrical load and operation; control light levels and color with added movement and daylight sensing controls; and be capable of monitoring operational activity.

FIG. 5. Using intelligent monitoring and controls like the Ee Monitor System enables the BOO to handle data collection and determine appropriate maintenance and building management functions.

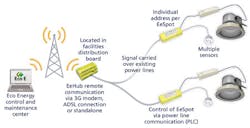

This empowers the BOO to manage the operational ergonomics with daily, weekly, or monthly reporting. The IMS monitors, controls, and provides real-time data of individual light fittings in all facilities, continuously maintaining the network and maximizing the reduction of energy use by intelligent control. Fig. 5 shows the Ee Monitor System by Eco E, which communicates using the existing power infrastructure and integrates with retrofitted SSL equipment to turn established facilities into smart buildings.

Future proofing and equipment lifecycle

Once a contract is established, it is important to work closely with the BOO to develop and incorporate the next generation of intelligently monitored technological devices. The aim should be to provide a center of excellence for that BOO's service or industry by providing energy reduction, enhancement of the operating conditions, and intelligent activity reporting.

This next state-of-the-art system should be tested and commissioned during the current contracted period and be ready for service for the next contracted period.

As a result of the equipment lifecycles, there is redundant equipment removed from each project that is still in good working order. Rather than destroy this equipment immediately, a good plan is to distribute it to needy organizations and small communities where its intermittent use will last for many years without a huge commercial cost.

Conclusion

To be successful in adopting and adapting new technology, it takes more than the knowledge and capability of a supplier and the BOO's representative. It takes a new and disruptive approach to the total method of specification, manufacture, supply, installation, and maintenance. Add to this specialist auditing, intelligent monitoring, and control as well as financing.

One can see the need for an ESCO providing LaaS where all of the specialist participants are working as a team and the responsibility is taken under one banner for a simple regular service fee for the life of the facility. This will maximize the sustainability of the project and mitigate the risk for the BOO.

Although disruptive to the industry, this model is easy to understand. But it must be technically capable and fully integrated with each part as important as the next for the solution to work.

LIONEL BARDEN is the managing director of Eco Energy Group Ltd. (Eco E; ecoenergygroup.com.au).