Understand the factors and adaptations that impact LED efficiency (MAGAZINE)

ALEXANDER WILM examines the factors that impact the efficiency of LED-based solid-state lighting systems, and considers product development options that balance application requirements and optimum efficiency.

Thanks to their various benefits, LEDs have become an integral part of general lighting applications as semiconductor light sources. For some time, LED efficiency has been significantly higher than that of conventional lighting technologies. But how do we define efficiency in a solid-state lighting (SSL) system? In ordinary everyday language, when we talk about the efficiency of light sources, we generally mean their luminous efficacy, which is measured in lumens per watt (lm/W), a metric that takes into account the sensitivity of the human eye. Another measure is efficiency characterized by radiometric power. Let's consider the impacts of efficacy and efficiency, and discuss the decision-making process product developers must follow, which impacts overall system efficiency.

Interested in articles & announcements on LED & lighting test & measurement?

Establishing an efficacy metric involves determining the photometric luminous flux of the light source (lm) in relation to the electrical input power (W). The alternative photometric radiation equivalent, conversely, does not consider the sensitivity of the human eye but is a pure efficiency measure. The optical radiometric output power (W) is divided by the electrical input power (W) to yield a percent efficiency. The efficiency of LEDs depends on many different factors. We will look at some of these in detail in this article.

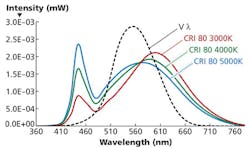

The efficiency of LEDs as a function of the color temperature

The choice of color temperature has a major influence on luminous efficacy and can be used within the framework of existing lighting regulations as a lever for the efficient planning of lighting solutions. LEDs with a high correlated color temperature (CCT) (e.g., 5000K) generally have a higher efficiency than those with a relatively low CCT (e.g., 3000K). The curves on the graph in Fig. 1 show the spectrums (or spectral power distributions - SPDs) of typical LEDs at different CCT values for general illumination with a color rendering index (CRI) of Ra >80. The SPD curves are overlaid on the human sensitivity curve Vλ (V lambda).

FIG. 1. The curves depict the spectral power distribution (SPD) of 80-CRI LEDs at different CCTs relative to human visual sensitivity.

To produce white light with an LED, a semiconductor chip that emits blue light is generally used. Some of this light is converted into light with longer wavelengths (green, yellow, and red light) by means of a converter mix or phosphor. Adding all these colors together then results in white light. This conversion process involves losses, however, which increase with the wavelength of the converted light. This increase in loss is because the difference in energy between light at a higher energy level (blue light) and light at a lower energy level (red light) is converted into heat. Minimizing losses calls for the precise alignment of the absorption and emission wavelengths of the converter.

A simplified scenario is sufficient, however, for explaining the basic principle. For warm color temperatures of 3000K, for example, it is necessary to convert a large amount of red light. This requirement leads, however, to greater losses, thereby reducing the luminous efficacy compared with 4000K. For high color temperatures of 5000K, blue light only needs to be converted into green light and not so much into red light, which is why the luminous efficacy increases in relation to 4000K. The efficacy comparison is depicted in Fig. 2.

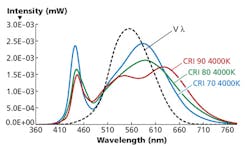

Influence of color rendering on the efficiency of LEDs

As already mentioned with regard to color temperature, the composition of the color spectrum based on the choice of a suitable converter has a decisive influence on the efficiency of the LED. The converter mix is developed specifically for different CRIs and is optimized in particular for the CRI as well as for efficiency. The differences between CRI 70, 80, and >90 can be seen very clearly in the rendering of red tones. To reproduce these tones as faithfully as possible, a high proportion of long-wave light is needed; in other words, light at the red end of the color spectrum.

FIG. 2. The graph depicts relative luminous efficacy at CRI Ra 80 for different CCTs.

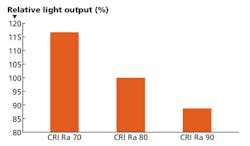

Fig. 3 provides typical SPDs for 4000K LEDs at different CRIs. The high red proportion of the CRI 90 version can be clearly seen. As already explained, producing this high proportion involves high losses. What's more, much of the red energy produced lies significantly outside the sensitivity curve of the human eye Vλ, which leads to an additional reduction in luminous efficacy. Whereas the influence of different color temperatures on the luminous efficacy of the LED is in the region of ±5%, the influence of the CRI for different values is typically more in the region of ±15% (Fig. 4).

FIG. 3. The curves depict the SPD of typical 4000K-CCT LEDs at different CRI values.

FIG. 4. The graph depicts relative luminous efficacy for different color rendering values (CRI Ra) at 4000K.

The freedom to choose the color temperature and CRI of an LED, however, is restricted by specifications, guidelines, and the particular requirements of a specific application. Similar effects are also seen with conventional lighting technologies.

The LED as a light source with adjustable efficiency

By comparison with conventional light sources, however, the LED opto-semiconductor offers a further dimension in which the efficiency or luminous efficacy can be adjusted and set on an application-specific basis by the luminaire manufacturer, namely the current density.

LEDs are usually grouped (or binned) in terms of their brightness and color for a certain operating current. For particular grouping conditions, there is therefore a typical efficiency that can be adjusted to suit the application and the desired level of luminous efficacy by varying the current density.

If, for example, we take an LED that has a luminous efficacy of 130 lm/W at the specified grouping current, we can reduce the operating current to 40%, which ultimately leads to a 20% increase in luminous efficacy to 156 lm/W. If the operating current is increased to 140%, the luminous efficacy will be reduced by 10% delivering 117 lm/W. Table 1 summarizes the variable current density scenario.

The efficiency curve also depends on other parameters, such as the operating temperature or maximum operating conditions that need to be met. The absolute luminous flux of the LED naturally changes at both operating points. We will take a closer look at this effect in the next section.

Use of more efficient LEDs to reduce system costs

In the course of their development, LEDs have become brighter and therefore more and more efficient. Some applications, however, do not necessarily need greater efficiency. So why is there such huge demand for brighter and brighter LEDs with ever greater efficiency? Without doubt, one reason is that more efficient light-emitting diodes can lead to significant cost reductions at the SSL system level.

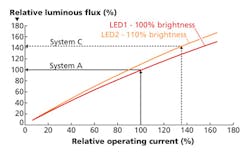

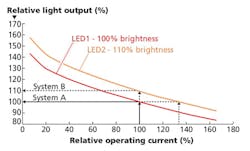

Let's consider an example. For the following comparison, we are assuming that we want to create a system or product with an efficiency and luminous flux of 100%. We have a choice here of two LEDs: LED 1 with a brightness of 100% and a more efficient LED 2 with a brightness of 110%. Figs. 5 and 6 graphically depict the system-level operating conditions based on the two LED options.

System A with LED 1 is used as the reference. At the normal operating current of 100%, this system has a relative efficiency of 100% and relative luminous flux value of 100%. The relative number of LEDs required in the system is also 100%.

If we use LED 2, we can realize System B in Fig. 5. In this system we operate the LEDs on the same current, and use the same number of LEDs. System B is therefore 10% more efficient and brighter. The brighter option might be a selling point for a luminaire, or might provide the luminaire manufacturer with options to change the operating parameters.

TABLE 1. Changes in current density relative to grouping or binning current specification have corresponding efficacy impacts.

Operating condition 1 | Grouping condition | Operating condition 2 | |

Current density (A/mm2) | 40% | 100% | 140% |

Efficiency (lm/W) | 120% | 100% | 90% |

Luminous flux (lm) | 43% | 100% | 130% |

TABLE 2. Theoretical LED system designs based on two differ LEDs illustrate the tradeoffs that product developers face.

System A with LED 1 | System B with LED 2 | System C with LED 2 | System D with LED 2 | |

Current density | 100% | 100% | 136% | 136% |

Efficiency | 100% | 110% | 100% | 100% |

Luminous flux | 100% | 110% | 142% | 100% |

Number of LEDs | 100% | 100% | 100% | 70% |

If this increased efficiency is not required at the system level, perhaps because the threshold for an energy-efficiency class has already been reached, we can reduce the efficiency back to 100% from 110% by increasing the current density. This means that our new System C will be even brighter in addition to the initial 10%, and for the same efficiency as System A will have a brightness level that is 42% higher than that of System A.

FIG. 5. The graph shows the change in luminous efficacy as a function of operating current.

FIG. 6. The graph shows the changes in luminous flux relative to the operating current.

But again the application may not require the greater output in luminous flux. Table 2 summarizes the scenario and suggests a System D option. Because System C is much brighter than System A, we have the option of reducing the number of LEDs. System D utilizes 70% of the number of LEDs in System A and thus significantly reduces the cost for the system.

This example can very easily be applied to systems with a large number of LEDs. It can also be used for a single-LED system if the luminous flux package can be reduced and a packaged LED with a smaller chip can be used. The level of savings in each individual case depends on various other parameters and may vary according to the operating point.

These examples presented here show that the choice of color temperature and also the CRI have a significant influence on the luminous efficacy of an LED. Specifically, this means that the higher the color temperature, the greater the luminous efficacy, and the higher the CRI, the lower the luminous efficacy. In this connection, a crucial difference between LEDs and conventional light sources is the fact that the efficiency of LEDs can be adjusted via the operating current. This option should be borne in mind with regard to LED systems in particular, as significant savings in LED costs could be made.

Links |

Our Developer Forum series focuses on design challenges and solutions to problems the typical LED system or component developer would face. Find articles that address power concerns, system efficiency, thermal management, materials selection, manufacturing, and more - below are just a few samples of our most popular articles. |

Simulation enables optimum LED street light heat-sink design |

Novel design and manufacturing techniques enable 3D LED lamps |

Overcome major LED-lighting design challenges with molded plastics |

Understand the hidden costs of free 0-10V LED dimming drivers |

ALEXANDER WILM is an application engineer at Osram Opto Semiconductors in Regensburg, Germany, responsible for lighting and luminaire concepts and for quality of light (osram-os.com).