Quantum dots enhance horticultural efficiency of sunlight in greenhouses

Horticultural lighting remains a hot topic as increasingly food, flowers, and cannabis are grown in controlled environment agriculture (CEA) settings either indoors or in greenhouses. Greenhouses have been thought by many to offer the best of both the outdoor world via sun exposure to plants and the ability to control the environment to a significant degree. But now UbiQD and Nanosys say they can improve the use of sunlight energy for greenhouse operations by leveraging quantum dots (QDs) and shifting the spectra in a way that allows plants to better utilize the radiated energy that is critical for photosynthesis and other plant-growth phenomena.

So this story is not about LED technology where manufacturers have long sought to replicate the spectral power distribution (SPD) of the sun. But in essence, research on LED-based horticultural lighting set the stage for this development. We have regularly described how solid-state lighting (SSL) enables growers to only deliver the wavelengths that plants require, and thereby optimize energy usage. For example, there are chlorophyll absorption peaks in the red and blue regions that are key to photosynthesis. We have also written about other important wavelengths such as in coverage of our HortiCann Light + Tech event and the earlier Horticultural Lighting Conferences.

Still, the horticultural lighting sector has been most focused on the 400–700-nm range of wavelengths that are referred to as photosynthetically active radiation (PAR). And the UbiQD and Nanosys news relates to converting some of the sun’s energy from outside the PAR range into PAR energy. The companies simplified the concept, saying that their technology creates “more photosynthetically efficient orange light that plants crave.”

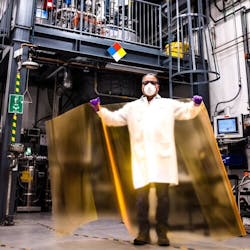

The secret sauce is the QDs and Nanosys is one of the largest manufacturers of those nanoparticles. UbiQD takes those QDs and embeds them into UbiGro plastic films or sheets that can be applied to the surface of the greenhouse.

QDs have been widely used in TV and display applications. The particles can be activated optically or electrically. If such a particle absorbs a photon from the sun or other source, it will in turn emit a photon of a different color in a similar manner to how phosphors operate when used with LEDs to make white light. The color or wavelength of light that a QD produces is based on the size of the particle. In particular, QDs produce much richer red wavelengths than do phosphors and thus the use in TVs to achieve a richer gamut. Nanosys allied with Samsung all the way back in 2010 and of course Samsung has been a leader in using QDs in TV applications.

Now in the horticultural sector, the QD technology may help increase the yield of greenhouses, even when used separately from LED technology. Of course, LED-based lighting is also used to supplement the sun in greenhouses, especially in northern regions where short days limit sun exposure.

And the opportunity for the QD suppliers may be substantial. “The greenhouse cover films market produces twenty times more area than the display industry and continues to grow in double digits on an annual basis,” said Jason Hartlove, CEO of Nanosys. “Greenhouses represent a massive opportunity for the unique benefits of quantum dot technology. We look forward to working with UbiQD to bring UbiGro to market with our industry-leading scale, cost-effectiveness, and highest-quality manufacturing standards.”

Learn more about the latest in horticultural lighting and other AgTech topics at HortiCann Light+Tech slated for Oct. 20 in San Jose, CA.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.

Maury Wright | Editor in Chief

Maury Wright is an electronics engineer turned technology journalist, who has focused specifically on the LED & Lighting industry for the past decade. Wright first wrote for LEDs Magazine as a contractor in 2010, and took over as Editor-in-Chief in 2012. He has broad experience in technology areas ranging from microprocessors to digital media to wireless networks that he gained over 30 years in the trade press. Wright has experience running global editorial operations, such as during his tenure as worldwide editorial director of EDN Magazine, and has been instrumental in launching publication websites going back to the earliest days of the Internet. Wright has won numerous industry awards, including multiple ASBPE national awards for B2B journalism excellence, and has received finalist recognition for LEDs Magazine in the FOLIO Eddie Awards. He received a BS in electrical engineering from Auburn University.