EMERGING TECHNOLOGY | Leveraging LED and 3D printing technology for a sustainable SSL paradigm – Part II

In Part I of a two-part series, we reviewed performance differences between fluorescent and LED luminaires in the ubiquitous linear luminaire form factor, and explained how the Sparkle luminaire concept was initiated to test and demonstrate the viability of additive manufacturing for next-generation lighting components and finished products. Part II will explore the intersection of component modularity, flexibility in customization, and design for disassembly, which contribute to the potential of the luminaire concept to disrupt and evolve traditional lighting manufacturing and distribution.

Editor’s note: Figures, tables, and footnotes have been numbered in consecutive order proceeding from Part I to Part II to maintain continuity.

Luminaire frame design

Part I concluded with a description of the Sparkle louver design that was engineered to mitigate glare and aid in obscuring the light sources from direct view by observers.

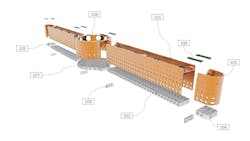

Proceeding to the frame design, the main chassis of the frame serves multiple purposes. As emphasized in the previous optomechanical and thermal component discussion, many of the frame features achieved via additive manufacturing would not be possible with traditional metal fabrication or machining techniques.

Two rows of holes at the bottom of the frame allow for light extraction and a sparkle effect. The holes may also serve to dampen or absorb sound in the environmentxii. In addition to the side holes and perforations, the top of the luminaire features a series of holes for accessory attachment both from below and above. Wire routing, hanging hardware, and light engine accessories can be friction-fit into the holes, facilitating disassembly while also passing a UL shake test. There is no need for adhesives or secondary hardware components such as screws. Fewer construction materials, hardware, and fastenings help to meet circular economy goals.

Another capability unique to additive manufacturing is the ability to print text on the component itself. For example, we were able to print disassembly instructions onto the upper cavity of the frame. While the information is hidden from direct view in the space, it is readily available for any workers interfacing with the luminaire in the field, which can be an important maintenance feature. A removable 3D-printed medallion also allows for a scannable QR code that guides workers to disassembly instructions for end-of-life refurbishment and disposal.

Improved maintenance scenarios are key to achieving circular economy goals in lightingxiii. Part of this strategy is the ability to house spare LED engines on the luminaire so the light source can be swapped for a similar LED if issues arise. Luminaires currently have limited capabilities for toolless servicing. Concerns with servicing LEDs in the field result from the LEDs coming from a particular bin, phosphor blend, and shifts that may occur in situ over time. For instance, LEDs are binned in three separate modes currently: output (in lumens,) color coordinates, and forward voltage. An AT0 LED module may be prioritized for output, and in the event the luminaire needs to be serviced, it is difficult to match the existing LED in color properties. Having an LED from the same batch not only reduces service time, but the user can also be assured that the LED will match.

A new type of engine

With phosphor technology improvements, LEDs have enjoyed rapid gains in device efficiency and color quality while prices have dropped. Two common small-format building blocks for commercial luminaires are the 3030 (3×3mm) and the 2630 (2.6×3mm) packages, typically outputting in the range of 30–60 lm.

Current trends in LED technology have done away with some of the traditional components of the low-format LED — specifically its packaging. Older LEDs (2630 and 3030) were housed in packaging that was sometimes an ablative material such as ceramic, but in most cases it was plastic. While inexpensive, there was a danger with temperatures and melting of the package. As a result, there are strict limitations on the drive current for low-power devices. Therefore, lumen ranges for the luminaire system are limited on the high end of output.

With the advent of chip-scale packaging (CSP) type LEDs, the industry eliminated the package component and freed us from the constraints of over-driving. As a result, there are many CSP LED packages that emit over 300 lm — in a much smaller footprint for better flux coupling. Furthermore, they have a wider drive current range, which allows for a wide range of product types as a function of lumen output. The Sparkle louver employs a novel LED package that can produce 250 lm (Fig. 4).

Given that a standard metric for specification of linear LED lighting systems today is 1,000 lm/nominal foot, we can see a scenario where four starboards with CSPs replace the 27 low-power devices that would be placed on a standard LED board — reducing the number of LEDs in a standard, 4-foot, semi-indirect luminaire (uplight and downlight boards) by 92% (in the case of Sparkle) and reducing the amount of PCB material by 84%.

Sparkle louver allows for less conspicuous spacing of the LED packages. Conventional processes use a diffuser (virgin plastic) below each downlight LED array. To achieve uniformity, LEDs are usually closely spaced (10mm pitch), the diffuser is placed a certain distance away, and reflectors are often used in conjunction. Sparkle louver employs individual CSP packages and much wider spacing (80mm pitch) with only local diffusers. Again, this uses less material while generating the same effect, to deliver on circularity objectives.

Still, it is important to understand the difference in the electrical configuration of the “standard” Level 2 boards. Because so many LEDs are used, LEDs (typically 3V nominally) are broken into strings with a number of LEDs arranged in series with multiple strings in parallel. Number of LEDs per board can vary dramatically. For example, a standard Zhaga linear board may feature an array of three strings of nine LEDs. Even among LED vendors, there is variation in the number of LEDs in a string and the number of strings on a board. Given that the electrical vias are created specifically for this board, the ability to reuse it afterwards is severely limited. Conversely, a starboard has a single channel in and a single channel out. The ability to refurbish and reuse not only for lighting applications but for other applications is optimized.

Materials and design for disassembly

Metal fabrication places significant strain on our environment. Copious amounts of water are used in the processing and recycling of metals. Mining raw materials creates noxious dust that compromises local air and water quality. Recycling processes also use a tremendous amount of natural resources, and one of the byproducts of recycling, dross, is considered highly hazardous and needs to be stored in special containers. Only a small percentage of commercial luminaires are recycled; most go directly into the waste stream.

One reason is the inability to easily separate luminaires into individual components due to the lack of common material and the use of paints or adhesives that cannot be removed. Uniformity of material was a top consideration for Sparkle. Each of the components — with the exception of the wiring, LED, and hanging hardware — is made of the same materials and can be recycled in the same waste stream. For example, one Sparkle configuration is made from reground plastic. This plastic can be reground and reused for luminaires or other types of products at end of life. Such a closed-loop system helps reduce the introduction of virgin materials, reduces emissions, and exponentially reduces the carbon footprint.

An aesthetic advantage of additive manufacturing is the range of colors at the designer’s disposal. Painting and anodization compromise the ability to recycle metal luminaires. Moreover, most manufacturers don’t paint luminaires themselves; they are sent out, creating an additional burden of carbon used in shipping and operational steps for quality assurance — not to mention waste in the form of rejects. With additive manufacturing, recycled material in the color choice and finish (matte, glossy) can be achieved in the printing process.

Modularity, design for disassembly, and a completely toolless configuration drove the Sparkle concept toward circular objectives. No screws or fasteners are used. Instead, we employed a series of 3D-printed keys and louver connectors for fastening. In addition, a lip extrudes beyond the frame with a corresponding cavity for accommodating the lip on the opposite side. In a conventional process, this detail would have required costly extra parts, fasteners, and different manufacturing techniques such as CNC machining and molding. Through additive manufacturing, we were able to include these features with no impact on costs.

A louver clip pulls the two adjoining louvers together and allows for seamless transition due to matching hole patterns. The shape of this clip could be easily achieved as a metal part, but the secondary holes on such a small and fragile part would be difficult to manufacture without damaging the part and taking too much time to set up given the need to make this component for pennies. Universal joining components and the lip/cavity technique allow luminaires to be assembled in myriad ways. Different radii corners as well as varying length body pieces allow for ease of assembly, in-situ servicing, and disassembly.

Diversity, equity, and inclusion

DEI goals were an important requirement for the Sparkle design — especially as they pertain to equal access to commercial lighting products. Traditional North American sales run through local agency networks. For small businesses or individual users, the ability to order commercial products is limited. Small orders tend to get de-emphasized. In addition, current practices of overages can make the price to the end user disproportionately expensive relative to the costs. It is for this reason that we offer these products for free. STL files for the various components (Fig. 6) can be downloaded from the Smash The Bulb website. There is a simple TLED version that can accept a standard 4-foot linear lamp.

Table 3 shows basic cost breakdowns along with amount of material used. We employed a basic slicing softwarexiv to ascertain material amounts as well as the expected costs for the material used. While the total weight of the print came to 417g and the cost $12.52, it is worth noting that a standard spool of 3D printed filament with 1,000 grams of filament can be purchased for $25. Premiums are charged at this date for recycled filament, but the price does not exceed $40/kg. A standard line-voltage TLED, tombstone connectors, and hanging hardware would keep total costs for a 4-foot, linear, semi-indirect luminaire well below $40. At roughly $10/linear foot, this represents a great savings over the state-of-the-art commercial luminaires, which could easily fetch 5–10 times that price.

There are other sustainability opportunities afforded by employing additive manufacturing. Luminaire designs could even be created to spec on site with a number of 3D printers set up as a mobile unit in a shipping container, further reducing carbon footprint from packaging and transport.

By realizing an inexpensive lighting unit and uncoupling it from the usual sales channels, we provide an opportunity for anyone with access to a desktop 3D printer to benefit from the design.

Conclusions

The perception that additive manufacturing is not ready to address the challenges of the commercial lighting industry is resonant of a time early in the adoption of LED technology. At the time (2007–2010), thought leaders in the lighting industry suspected that LEDs may be suitable for niche applications such as undercabinet lighting, but there would always be a place for the technologies it was being poised to replace (metal halide, fluorescent, and incandescent). Today, we see that this is not the case, and that there likely isn’t a commercial lighting application where LEDs haven’t or will not dominate in the future (such as UV lighting). Much the same can be said about additive manufacturing. Given the abilities to customize, lower carbon footprint for products, reduce operational steps/complexities, and — most importantly — achieve results other technologies cannot, additive manufacturing is a viable solution to replace metal-based luminaire manufacturing soon.

Disclaimer: The design and concept of Sparkle discussed in this article are filed with the U.S. PTO and designated as Patent Pending.

FOOTNOTES

xiiCurrently, no sound testing has been performed on the sample/prototype and cannot be verified.

xiiiK. Hickox and A. Smith, “Strategies for achieving circular economy goals in the lighting industry through design for disassembly-based methodologies,” Light-Symp-2022. IOP Conf. Series: Earth and Environmental Sci., 1099 (2022) 012004.

xivIdea maker version 4.2.1

DON PEIFER is a serial entrepreneur and lighting innovator based in Silicon Valley. With a master’s of architectural sciences in lighting from the Lighting Research Center at RPI, he has worked as a lighting designer and an executive in the lighting and controls sector for nearly two decades. Peifer was one of four winners of the DOE L-Prize Concept Phase. For more information on Sparkle, visit smashthebulb.com.

Follow our LinkedIn page for our latest news updates, contributed articles, and commentary, and our Facebook page for events announcements and more. You can also find us on the X platform.

Donald Peifer

DONALD A. PEIFER, founder of Smash the Bulb, LLC, is a lighting consultant based in Silicon Valley. With a master’s of architectural sciences in lighting from the Lighting Research Center at Rensselaer Polytechnic Institute, he has worked as a lighting designer and an executive in the lighting and controls sector for nearly two decades. Peifer continues to push the boundaries of lighting innovation and seek to provide novel products through his firm Smash the Bulb.

![The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.] The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.]](https://img.ledsmagazine.com/files/base/ebm/leds/image/2024/08/66be810888ae93f656446f61-dreamstime_m_265700653.png?auto=format,compress&fit=&q=45&h=139&height=139&w=250&width=250)