RPI team develops UV-C medical mask disinfector for Mt. Sinai

The coronavirus pandemic has driven significant interest in ultraviolet (UV) light as a way to kill the pathogen and specifically UV-C (100–280-nm) emission that will kill the virus but that also can be dangerous for humans. A cross-disciplinary engineering team from Rensselaer Polytechnic Institute (RPI), including engineers from the Center for Lighting Enabled Systems & Applications (LESA) laboratory rushed a design of a mask-disinfection system into reality after Mt. Sinai hospital in New York City asked for help in sterilizing personal protective equipment (PPE) used by frontline personnel treating COVID-19 patients. The system developed in just a matter of weeks is far from a laboratory prototype but rather a system that can disinfect thousands of medical masks each day.

There has been good science published suggesting that UV-C can kill coronavirus. For example, UV-LED manufacturer Seoul Viosys published research from Korea University asserting that the Seoul UV-C LEDs could achieve 99.9% sterilization in 30 seconds of exposure.

Still, the RPI team had to research doses needed to kill coronavirus, with the dose determined by radiometric output power of a UV source and exposure duration. As for the system and the mechanical design, the team faced another formidable challenge. It would be relatively easy to develop a passive design to disinfect a few masks at a time, but the RPI team delivered a mechanical system capable of carrying masks through the treatment continuously.

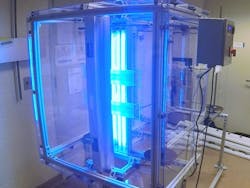

To understand the concept of the system, a quick look at a LESA lab video might be very informative. Bob Karlicek, director of the LESA lab and a key leader of the effort, refers to the structure as vertical with the mechanics carrying masks between two mercury-based disinfection lamps. UV-C LEDs would be an alternative for the light source, although Karlicek said the LEDs lack the reliability of the mercury lamps and cost more for now.

That vertical design enables high throughput and front and back disinfection of masks in the machine that has an 8×8-ft footprint. “Since UV-C radiation is a line-of-sight disinfection process, if there’s any shadow from the mask or any material blocking the access of UV-C radiation to the mask, you’re not going to disinfect that part,” Karlicek said. “We elected to come up with a system that allowed us to run the masks vertically so we could simultaneously expose the masks from both the front and the back without blocking any UV-C radiation.”

Related: Getting on the same wavelength with the experts

The design came to life through the efforts of many RPI departments starting with Karlicek and LESA. Arunas Tuzikas, another LESA engineer, and Mohammed Alnaggar, an assistant professor of civil and environmental engineering, worked on the design and construction.

The RPI Center for Biotechnology and Interdisciplinary Studies (CBIS) was also actively involved, including CBIS director Deepak Vashishth. CBIS senior research staff Brigitte Arduini, Jason Davis, and Sergey Pryshchep contributed to the project. And CBIS doctoral students Deepika Vaidyanathan and Sneha Gopal, working in a lab run by Jonathan Dordick, a professor of chemical and biological engineering, handled the data analysis leading to proper dosage.

Like some famed soup that couldn’t be too hot or cold, the dosage had to be just right. “If the dose is too high, the UV-C radiation can damage the elastic straps, causing them to break after a number of disinfection cycles,” said Karlicek. “We also didn’t want the dose to be too low, because then we wouldn’t be able to disinfect the mask.” The power of the lamp and the speed of the mask carriage system determine the dose.

Without question, the complexity of the system delivered in such a short period of time is very impressive. Masks are loaded onto the vertical holders in the system that move along tracks and through the UV-C bath. The walls of the system are made with Lexan, which blocks the UV rays, although the system isn’t sealed because the masks must be loaded and unloaded from the carriage system. So Karlicek said operators would still wear eye protection.

“Normally these things take a very long period of time, but given the national situation, I think there is an understanding at all levels that we need to look for solutions which are stable, good, and safe, and are delivered quickly,” Vashishth said. “I think this is an example of where we came together to deliver a solution, and hopefully, this is going to be useful to the healthcare professionals and frontline workers.”

We’d again remind everyone that UV energy must be handled with care. It’s a great tool but demands respect. The IES has issued excellent guidance of the situation.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.

Maury Wright | Editor in Chief

Maury Wright is an electronics engineer turned technology journalist, who has focused specifically on the LED & Lighting industry for the past decade. Wright first wrote for LEDs Magazine as a contractor in 2010, and took over as Editor-in-Chief in 2012. He has broad experience in technology areas ranging from microprocessors to digital media to wireless networks that he gained over 30 years in the trade press. Wright has experience running global editorial operations, such as during his tenure as worldwide editorial director of EDN Magazine, and has been instrumental in launching publication websites going back to the earliest days of the Internet. Wright has won numerous industry awards, including multiple ASBPE national awards for B2B journalism excellence, and has received finalist recognition for LEDs Magazine in the FOLIO Eddie Awards. He received a BS in electrical engineering from Auburn University.