Optimized LED headlamp control architecture broadens automotive SSL opportunity (MAGAZINE)

The automotive sector is very focused on technology right now as manufacturers strive to make vehicles of all types more reliable, efficient, lighter, and lower cost — and of course more stylish. In many areas of the vehicle, electrical systems are replacing mechanical and solid-state devices are proliferating including LED-based solid-state lighting (SSL) in roles within the cabin and in exterior applications. Even the traditionally simple headlamp has not escaped attention as automakers seek more efficient implementations than the halogen and high-intensity discharge (HID) solutions that have been the mainstay for many years. LEDs can deliver efficiency and freedom of form that equals style and increased functionality. While such advanced solutions are available, their cost has tended to make them more appropriate for high-end vehicles, but here we will propose an architecture that can bring SSL into the realm of even entry-level vehicles.

Automotive lighting background and trends

Indeed, the general trend for rapid technology change in the automotive world includes the headlamp. Automotive designers seek to make them more sophisticated and therefore safer; that ranges to the extreme such as designs with adaptive drive beams or what have been called matrix headlamps. But even in simpler designs, LEDs deliver the efficiency inherent in the SSL technology and afford the ability of better beam control that equates to better safety. Moreover, the LED has the inherent capacity to be fitted in many places where traditional lighting would not fit — spawning new concepts and applications.

In the world of automotive lighting, halogen lamps have long been the dominant technology for headlamps, sharing a segment of the luxury market with xenon-based HID technology since the 1990s. With higher efficiency and longer operating life, LEDs are proving to be a more disruptive technology. After initial adoption in premium models, suppliers now are deploying components that will allow penetration into the mainstream market segments.

Tailoring the lighting approach to suit the vehicle

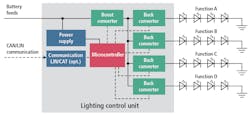

There are two primary approaches to the design of mainstream automotive lamp control/driver systems. Separated by performance and cost, both approaches are important in automotive applications. In premium applications, the intermediate voltage approach is used. This is both scalable, supporting four to six or even more LED channels, and flexible as it can work with LED/string voltages from 2–50V and currents from 100 mA–2A. Fig. 1 depicts a block diagram of such a headlamp subsystem.

A typical intermediate voltage solution such as in the figure consists of a boost driver to increase the battery voltage and a dedicated buck driver for each LED string that corresponds to a single light in the headlamp module [headlamp beam, turn indicator or daylight running light (DRL)]. A microcontroller controls the system, in particular the boost driver and each of the buck drivers. The power converters are typically asynchronous technology and achieve efficiencies in the range of 80–85%. The final element of this approach is what the auto industry refers to as a system basis chip (SBC) that includes a power supply, watchdog function, and CAN bus transceiver, allowing the lighting module to communicate with the wider vehicle systems.

While the intermediate voltage approach is well-suited to higher-end premium vehicles, it is quite component-hungry, especially in terms of the buck and boost converters. Scalability and support for a wide range of voltage outputs on different strings comes at a price and such architectural approaches are difficult to optimize for cost.

Mid-range and entry-level opportunity

Wider adoption of SSL in mid-range and entry-level vehicles is forecast to grow to millions of vehicles that will be on the road with LED technology. Realizing such

expanded adoption in the very near future requires a different approach in the driver/controller subsystem. Instead of having a single buck driver per light/LED string, a cost-optimized approach has a single centralized and greater than 90% efficient buck-boost driver. This centralized driver concept provides power for all of the lights in the system. The flow of current to the lights is controlled by several low-loss MOSFETs, or switching transistors, that are controlled from the microcontroller via a level shifter.

As with the intermediate voltage approach, a cost-optimized solution also includes a dedicated microcontroller and an SBC, such as depicted in Fig. 2. Comparing the two approaches, the cost-optimized approach has a single DC/DC converter as opposed to five. It does include more MOSFETs — one for each LED string, but has far fewer power inductors, diodes, and resistors. A typical installation requires, on average, 17 fewer components.

The higher efficiency of the cost-optimized approach results in a 50% reduction in power losses, which means that the system requires less cooling/heatsinking. A smaller heatsink also costs less. Coupled with the reduction in component count, the end result is a smaller and less costly solution, albeit with less flexibility and scalability.

Tradeoffs and solutions

There are tradeoffs to this approach to driving multiple LEDs/strings. This cost-optimized approach does switch lights in and out of the chain, perhaps as the system switches from high beam to low beam as required. Such switching can lead to current spikes in the output that could be harmful to the LEDs that remain powered, as seen in Fig. 3.

The product developer can address the potential for damage through a technique known as Fast Output Discharge (FOD) whereby the switching of the converter is suspended for a short period of time while the half-bridge (H-bridge) within the buck-boost driver discharges the output capacitor to the target voltage, as seen in Fig. 4. During this time called TPREP, the bypass is altered to include only the required lights and then the buck boost resumes switching with no current spike. This process happens in a very short duration and, as a result, human eyes cannot discern the off period due to persistence of vision.

Today, product developers can utilize a driver IC that integrates such FOD support — an H-bridge buck-boost driver designed to support cost-optimized automotive

lighting applications. Infineon, for example, offers such a device as part of the LITIX range of devices and offers both constant- current and constant-voltage control of LEDs. It is specifically designed to drive high-power LEDs, or laser modules, in automotive applications with efficiencies up to 96% and can supply complete headlamp lighting arrays (low beam, high beam, DRL, and direction indicators) from a single DC/DC converter.

The device operates across the automotive voltage range, accepts input voltages in the range 4.5–40V, is compatible with a wide range of LEDs requiring forward voltages in the range 2V up to 55V. LED current accuracy is ±3% (at TJ = 25°C). Infineon’s LITIX are qualified to the AEC (Automotive Electronics Council) specifications, meaning the ICs are capable of operating reliably in the challenging environment of the auto.

The novel circuit improves dynamic behavior, especially with regard to the rapid load changes and current spikes that can be present in cost-optimized, multi-string

SSL driver architectures. The device is optimized for EMI and includes an automatic spread spectrum feature. It also includes a limp home function that ensures the presence of lighting in the case of fault conditions, allowing the vehicle to be driven safely to a repair facility.

To shorten the development cycle, Infineon has produced a solution demonstrator that allows for an intermediate voltage solution and cost-optimized solution to be directly compared.

Summary

Technology within the automotive industry is rapidly changing and one of the areas of rapid change is in the area of vehicle lighting. The fundamental technology is rapidly moving from halogen to LED technology, which will dominate the market within just a few years.

While much of the development effort so far has been directed toward creating sophisticated LED-based lighting solutions for premium vehicles, with the widespread adoption of LEDs in vehicle lighting, these will soon become the preferred solution in mid-range vehicles. Predicted annual sales of 25 million mid-range vehicles with LED lighting mean that a new driver/controller approach is required, specifically to address this sector.

The cost-optimized approach trades some flexibility and scalability to deliver a solution that uses far fewer components to drive vehicle lights from a single buck-boost DC/DC converter with intelligently controlled MOSFET switching to control the flow of current to the lights. With dramatically increased efficiency as high as 96% percent, this approach delivers a smaller, more efficient, and lower-cost solution for future mid-range vehicles.

Get to know our expert

ANDRES ZAVALA is segment marketing manager at Infineon Technologies. He has worked with multiple semiconductor companies, developing microcontrollers and other products primarily in automotive applications and industrial markets. Zavala has held positions at Avnet Electronics Marketing, Freescale Semiconductor, and Motorola, and also served as a professor of electronics engineering at ITESM Campus Chihuahua in Mexico. He has a bachelors degree in electrical and electronics engineering from ITESO (Instituto Tecnologico y de Estudios Superiores de Occidente) - Jesuit University of Guadalajara, and a masters of business administration from ITESM ( (Instituto Tecnologico y de Estudios Superiores de Monterrey).

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.