Lumileds packaged LED delivers consistency in output to 1% dimming levels (UPDATED)

Lumileds has announced the Luxeon 3030 HE Plus Deep Dimming LED portfolio intended specifically for applications where lighting will be routinely dimmed to very low levels. The company said products will output uniform flux even when dimmed to 1% of maximum whereas many solid-state lighting (SSL) products exhibit inconsistent flux output when dimmed. The new mid-power, 3×3-mm packaged LEDs will target applications such as linear luminaires.

The so-called deep-dimming nonuniformity isn’t necessarily a well-known problem because the flux difference may not be evident at full output or even moderate dim levels. LEDs are binned for color and flux uniformity. And Lumileds was a pioneer in what it called hot binning, which it launched at Strategies in Light back in 2011. By testing and binning LEDs at actual operating temperature, better output consistency, especially in color point, was achieved. But almost a decade later, Lumileds and others are still chasing perfect uniformity in all operating conditions.

“Inconsistent flux performance has long been a problem for luminaire manufacturers, and they’ve found work-arounds by either adding components or managing LED selection from the bins they receive. Both work-arounds add cost, complexity, and time to the manufacturing process,” said Mei Yi, product marketing manager at Lumileds. “With Luxeon 3030 HE Plus Deep Dimming we provide consistent flux performance across the dimming range directly at the LED level.”

The workarounds mentioned above are costly in terms of time, inventory, and/or driver-circuit complexity. A luminaire development and manufacturing team can take a brute force approach and further test LEDs for uniformity at very low levels. But that approach creates an inventory nightmare and also impacts inventory utilization. Or the development team can add active current-control to allow matching of flux output.

To illustrate the issue, Lumileds has images of some LED tubes that are representative of how rectilinear luminaires are constructed. In such a 48-in. product, a typical design would use six rectangular light engines or segments with each about 8 in. long. The 12–14 LEDs in each segment are connected in series delivering more efficient driver circuits through a series forward voltage of 40–48V. The high voltage level equates to driver efficiency because the line voltage does not have to drop at the magnitude that it would to drive LEDs in a parallel topology.

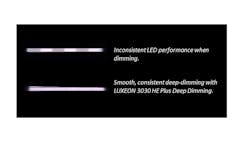

The nearby image shows two tubes, the top of which is based on typical mid-power LED and the bottom of which is based on the new Deep Dimming LEDs. The non-uniformity is clearly seen in the top tube when operated at 3% of maximum whereas the bottom tube retains uniformity.

Most developers specify hot-binned LEDs these days to ensure color consistency. And the new Lumileds products have 3 MacAdam ellipse or SDCM color bins. The culprit in the photo is variation in the forward voltage of the individual LEDs used in the top tube in the photo. As forward voltage (or VF) varies, so does the current flowing through the individual LED and the flux level produced.

Lumileds said that at very low current levels, small VF level variation creates the noticeable difference. Consider that a mid-power LED driven nominally at 65 mA would be driven at 0.65 mA when dimmed to 1%. A VF mismatch of more than 0.10V can cause a problem.

Lumileds will not say how it is holding VF to within 0.10V in the new family. The company did say that it is not doing further binning and therefore dealing with yield losses to deliver the uniformity. Instead, it appears there is some step involved in the manufacturing process. Lumileds has been behind quite a few innovations in mid-power LEDs over the last decade. After the aforementioned announcement of hot binning in 2011, the company brought that feature to mid-power 3030 devices in 2013.

The company will offer the Deep Dimming LEDs over the range of 2700K to 6500K CCT, and with CRI of 80 or 90. Efficacy ranges from 162–210 lm/W. And the VF spec is 2.71V ±0.05V.

*Updated Sept. 24, 2020 11:45 AM to correct units of drive power.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.

Maury Wright | Editor in Chief

Maury Wright is an electronics engineer turned technology journalist, who has focused specifically on the LED & Lighting industry for the past decade. Wright first wrote for LEDs Magazine as a contractor in 2010, and took over as Editor-in-Chief in 2012. He has broad experience in technology areas ranging from microprocessors to digital media to wireless networks that he gained over 30 years in the trade press. Wright has experience running global editorial operations, such as during his tenure as worldwide editorial director of EDN Magazine, and has been instrumental in launching publication websites going back to the earliest days of the Internet. Wright has won numerous industry awards, including multiple ASBPE national awards for B2B journalism excellence, and has received finalist recognition for LEDs Magazine in the FOLIO Eddie Awards. He received a BS in electrical engineering from Auburn University.