Seoul Semiconductor moves to emphasize CSP LEDs across SSL applications

Seoul Semiconductor has issued two recent press releases on the technology that the company calls WICOP indicating a significant uptake on the chip-scale package (CSP)-type technology. Seoul is already succeeding broadly with WICOP in the automotive application area and believes it will win high-power LED sockets in general solid-state lighting (SSL), automotive, and horticultural lighting. The company also plans SunLike-branded products in WICOP flavors, and that implies a target on lighting for health and wellbeing and high-end retail applications.

The WICOP technology emerged concurrent with the packaged LEDs industry moving to deliver LEDs in CSPs. CSP technology promised to reduce package costs, improve thermal performance, and ultimately dominate the industry. You rarely see Seoul use the acronym for WICOP these days, but when the early products were announced we reported the branding as wafer-level integrated chip on PCB, and Seoul was among the first LED makers to scale CSP technology over a range of LED footprint sizes. Lumileds had been first with a CSP LED a few years earlier.

Seoul has long claimed that WICOP differed in important ways from the other CSP offerings on the market, and that those differences delivered a performance advantage. Moreover, the company has long claimed that some companies have illegally utilized Seoul-patented techniques in CSP offerings, again making such a claim last week. But the company has never fully explained those claims.

We would not have written about the intellectual property (IP) claims Seoul made recently. But the stated goals of WICOP are quite impressive. And Seoul is taking varied technology and packaging approaches to pursue its goals.

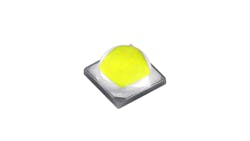

Last week, the company said it would offer some WICOP devices in packages that look like legacy high-power LEDs including primary optics and a thermally-stable substrate. Such a product might target street lights to low/high-bay lighting. Seoul said the global market for such LEDs is around $2B (billion) (annually). Seoul believes it can capture the majority of the market with its Z5M4 LED (pictured) taking the share from companies that still rely on a vertical LED architecture in the application space. And the company said it would use the same product family to win share in camera flash and some automotive applications. It is worth noting, however, that encapsulating a CSP LED in a high-power package inherently eliminates some of the package-light advantages of CSP.

Subsequently, Seoul’s second press release specifically addressed the automotive market and a new architecture that the company calls WICOP TE (top electrode). Once again, the concept runs somewhat counter to the CSP concept where such LEDs would presumably be attached directly to thermal and electric substrates. But Seoul says that in the automotive headlamp application, that it can ramp performance more by attaching to a thermal surface directly even while using what are essentially wirebonds to connect with the electric substrate. Seoul said the technology will be especially important in electric vehicles where efficiency is even more important than in legacy autos.

Meanwhile, the company said it had already enjoyed great success with WICOP in the automotive market. It reported that 102 car models from 32 customers use WICOP. And Seoul claimed there are even more ongoing projects. The company pegs the automotive market opportunity at $2.7B.

Seoul did not provide any details about SunLike spectra coming to WICOP LEDs. Just a couple of weeks back, Seoul had announced that it was now the sole owner of the SunLike technology that was originally developed in partnership with Toshiba Materials. Seoul will decide when and how to bring the three-phosphor mix and violet emitter to WICOP. That should be a relatively simple task in a high-power package. It could be more difficult in versions with no primary optic. SunLike will enable access to exceptional light quality and spectra that can be tuned for horticultural or circadian lighting.

LEDs Magazine chief editor MAURY WRIGHT is an electronics engineer turned technology journalist, who has focused specifically on the LED & Lighting industry for the past decade.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.

Maury Wright | Editor in Chief

Maury Wright is an electronics engineer turned technology journalist, who has focused specifically on the LED & Lighting industry for the past decade. Wright first wrote for LEDs Magazine as a contractor in 2010, and took over as Editor-in-Chief in 2012. He has broad experience in technology areas ranging from microprocessors to digital media to wireless networks that he gained over 30 years in the trade press. Wright has experience running global editorial operations, such as during his tenure as worldwide editorial director of EDN Magazine, and has been instrumental in launching publication websites going back to the earliest days of the Internet. Wright has won numerous industry awards, including multiple ASBPE national awards for B2B journalism excellence, and has received finalist recognition for LEDs Magazine in the FOLIO Eddie Awards. He received a BS in electrical engineering from Auburn University.