Plastic light diffusion systems match LED lighting needs - Part 2 (MAGAZINE)

Understanding optical systems phenomena such as reflection and transmission enables SSL development teams to choose proper additives and production techniques to achieve desired beam patterns, explains GABI BAR.

In recent years, LEDs have gained wide attention as a very low-power-consumption alternative to conventional indoor and outdoor light sources. Due to the LED's small size, an extensive range of design options is available for constructing the indoor and outdoor light fixtures. Nevertheless, when using LEDs to replace conventional light bulbs and fluorescent-tube lamps, the requirements to meet light intensity and light emission uniformity specifications remain in place. Part of that challenge relies on effective optical subsystem design, and this second article of a two-part series will describe the optical effects that can be achieved in solid-state lighting (SSL) systems.

Interested in articles & announcements on plastic light diffusers and SSL optics?

To grasp where we are headed here, consider a baseline requirement for most LED-based luminaires. Although LEDs are spot sources, a "spot-like" light emission is not desired in most cases. Therefore, one of the main challenges in LED design is to be able to create uniform diffused light while minimizing loss of light intensity. Furthermore, the diffusing agent should be lightweight and allow for both high and low environmental temperature conditions. Finally, it should be economical to manufacture in high volumes.

Part one of this two-part series was published in the July/August edition of LEDs Magazine. There we discussed light diffusion solutions from the perspective of selecting the optimal polymer carrier, and various techniques to measure light diffusion properties were presented. The current part will focus on the light diffusion agent itself, which in turn is incorporated into the selected carrier in order to provide optimal light diffusion properties of the complete system.

FIG. 1. The image illustrates specular reflection of clouds on the surface of a pond. A still pond would deliver a mirror-like effect and would be considered regular reflection. The ripples in the water depicted in the image results in what is called diffuse reflection. (Photo credit: Prahbu B. Doss, via Flickr at http://bit.ly/2xYVM4h.)

Optical system phenomena

In order to understand the light diffusion mechanism, the interaction between light and translucent material needs to be understood. When visible light interacts with translucent matter, several phenomena simultaneously occur. The most predominant for the systems of interest in LED coverings are reflection and transmission.

Reflection occurs when light bounces from a surface to the eye. Reflection may be specular (regular) or diffuse. If the surface is very smooth, like a mirror, the reflected light can form a very clear image. This is known as regular or specular reflection.

Consider the surface of a lake as an example. If you see a lake with perfectly still water, you will likely see a specular reflection of trees or clouds that rivals what you might see from a mirror. Conversely, when light is reflected from a rough surface, the waves of the light are reflected in many different directions, so a clear image does not form. This is called diffuse reflection. As seen in Fig. 1, even minute ripples in the water cause diffuse reflection of the clouds.

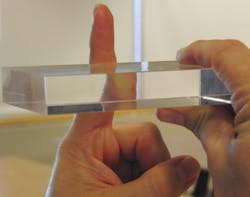

Transmission of light occurs when light passes completely through matter. As light is transmitted, it may pass straight through or it may be refracted or scattered as it passes through. When light is refracted, it changes speed and direction as it passes into a new medium as shown in Fig. 2. Moreover, the difference in the refractive index of air and the transparent material shown in the figures results in a discontinuity of the object viewed through the material. You can see a similar effect if you look at a straw in a glass of water and see the discontinuity between the portion of the straw below the water and the portion above the water in air.

Diffuse transmission occurs when light passes through transparent media that contains small transparent particles; a portion of the light no longer travels in a straight path, since when the particles are encountered, the light may be refracted or scattered or both. The result is dispersion of the transmitted light, also referred to as diffuse transmission. In fact, this is the mechanism of the light diffusion system.

The extent of light diffusion is based on many parameters and is discussed in depth in this article. An everyday example of a light diffusion system is shown in Fig. 3. Light from automotive headlamps in rain is an example of a case when light encounters tiny particles and spreads out in many directions.

FIG. 2. Light travels at a slower speed in varying materials such as plastics, water, and air. The difference in refractive index (RI) between the plastic and the air causes the apparent discontinuity in the image of the finger.

Classifying matter by its interaction with light

Any matter can be classified by its interaction with light. In fact, there are three basic options for interactions of matter with light:

- Matter can be transparent to light

- Matter can be translucent to light

- Matter can be opaque to light

Light diffuser systems fall within the second category. In other words, the resulting materials are translucent to light. Translucent materials can be characterized by:

- The total amount of light that passes through the matter (as opposed to absorbed or reflected)

- The extent to which the transmitted light is diffused

- Parameters of the matter that affect translucency

Now, let's discuss the relationship of characteristics of optical matter and translucency. In order to understand this section, the term of refractive index must be further explained. The refractive index, n, also known as the index of refraction, is a dimensionless number that describes how light propagates through a particular medium, based on the following equation:

In the equation, c is the speed (velocity) of light in a vacuum and v is the velocity of light in the medium. For example, the refractive index of polycarbonate (PC) is 1.58, meaning that light travels 1.58 times faster in a vacuum than it does in PC.

Media and particles

So now the optimal diffusion system can be discussed, and we see that it takes two to tango. For quality light diffusion systems, both transparent media and transparent particles embedded in the media are needed. The aforementioned case of water droplets in the air is a good example of this combination.

In the case of a light diffuser system, the transparent media previously explained corresponds to the polymer, as discussed in depth in the first article of this series. Practically, there are only two options for a carrier for light diffusion systems: PC or poly-methyl-methacrylate (PMMA). The more challenging question is what kind of particles should be used to give the water-droplet-like diffuser effect in the host (or carrier) polymer.

The types of light diffuser (LD) additives in use over the last 20 years have been revolutionary if we compare recent additives to the type of additives used before. The first light diffuser additives in transparent plastics were quite primitive in terms of technology and performance. Nevertheless, they were satisfactory for roofing applications with PC or PMMA sheets.

Sheets producers, via their compounders, were using various materials to add LD properties into the sheets. Most of the additives were based on minerals, like BaSO4 (barium sulfate), ZnO (zinc oxide), ZnS (zinc sulfide), CaCO3 (calcium carbonate), and even TiO2 (titanium dioxide). The latter is still in use today, but only for white coloring. The main advantage of using minerals as a light diffusing agent is the low cost. Often the costs of the LD additives were lower than the polymer itself.

State-of-the-art additives

Today, with the new LD additive technology, the LD additives by themselves can cost even ten times more than the host polymer on an equal weight basis. Still, you may be surprised at the reason for the transition because cost isn't a direct factor.

While the mineral approach offered a significant cost advantage, using minerals as a light diffusing agent required a relatively high dosing level to get acceptable moderate diffusing properties. But the high loadings consequently led to a reduction in mechanical properties and a significant reduction in total light transmission (LT). Where LT of the natural polymer is 90%, the mineral additives could lower LT down to 60%-65%. In comparison, today's systems can maintain an LT level of 80%-85%.

Why is there such a difference? The answer lies in the parameters that affect the LD performance while maintaining the LT. The most notable parameters are as follows.

FIG. 3. Scattering occurs when light encounters tiny particles of matter and spreads out in many directions. Here beams of light from a car's headlights are shining through fog. The water droplets in the air disperse the transmitted light thereby creating a natural light diffusion system. (Photo credit: Ruth E. Hendricks, via http://bit.ly/2kk9rxC.)

LD additive concentration seems an obvious factor and is. Increasing the LD additive concentration in the polymer will increase light diffusion properties. On the other hand, it will also reduce the total amount of light transmitted. The term luminance is a measure of the intensity of the light emitted from a surface. The reduction in luminance versus concentration is shown in Fig. 4. Therefore, with any type of LD additive, concentration must be optimized to account for the tradeoff between LD and LT.

LD additive reflective index (RI) also is a key parameter. When selecting the RI of the LD additive, the RI of the host polymer must be taken into consideration. As the difference in RI between the carrier and the LD additive increases, the extent of light diffusion will increase. Thus, a lower concentration of LD additive can be used to give the same light diffusion level. On the other hand, light transmission will drop faster. The dependency of luminance on RI is also shown in Fig. 4. In other words, an LD system with a small RI difference between the host polymer and the LD additive will require a higher additive loading, but will result in a higher luminance as compared to an additive with a larger RI difference.

LD additive particle size comes into play in scattering. A smaller particle size will be more effective in scattering the light. This makes sense, since for the same LD additive concentration by weight, light will pass from the polymer media to the LD additive media a higher number of times in the case of smaller particle size. This will result in a greater light diffusing effect. However, when considering LT, experiments indicate that there is an optimal particle size of 2-3 μm (microns). A particle size that is larger or smaller than this range will result in lower LT. A luminance experiment based on different particle sizes is shown in Fig. 5.

FIG. 4. The graph shows the dependence of luminance on the concentration and type of LD additive in polycarbonate. The RI of PC is 1.58. Microbeads with a higher RI difference (relative to the host polymer) are more effective in diffusion properties, but luminance drops much faster.

LD additive particle size distribution is a concern, as might be expected. For a given average particle size, experiments indicate that a uniform particle size allows for higher luminance as compared to having polydispersity of the particle size.

LD additive shape also comes into play. Let's assume that the LD additive is composed of pure water, but not in a tiny spherical shape; rather, it is crushed ice in the form of small, thin irregular plates. Would the level of transmitted light will be the same? Also, here, the answer is no. Although ice has the same chemical composition as water, the shape and form of the particles impacts the LT level. The reason is that when light meets a smooth surface of transparent material, most of the light will be transmitted through the object. This is the case with a spherical shape like the water droplets. But when the LD additive is in an irregular form, light will be reflected or scattered to a greater extent.

FIG. 5. The graph shows the dependence of luminance on particle size for the same type of LD additive. Optimal size range is between 2-3 μm. Smaller or larger particle size results in lower luminance levels. For particle sizes of 4.5 μm or higher, the luminance level has a very low dependency on concentration.

Light transmission through the LD additive is the final parameter we will discuss here. If instead of water droplets, the same light beams were projecting on cola droplets with the same droplet size and concentration, would the level of light reaching our eyes from the car beams be the same? The answer is clear: The level of light transmission will be lower. Thus, the extent of light transmission of the LD additives is also of importance.

Industrial water droplets

After understanding the required properties of the LD additive, we can now discuss what we call industrial water droplets that might be used as light diffusing agents. For the last two decades in the PC sheets industry, the traditional minerals used as LD additives were replaced by cross-linked polymeric microbeads. Microbeads are also used in the production of flat LCD screens. Originally, polymeric microbeads were developed for the cosmetic industry.

Fig. 6 is a microscopic image of some Tosaf microbeads. The microbead diameter ranges from 0.8 μm up to 40 μm in some cases. The image is a picture of typical pure microbeads and not compounded microbeads.

These microbeads are the ideal light diffusing agents in PC and PMMA. The additives are transparent, spherical, uniform in size, and available in a range of RI's based on the type of polymer utilized. In addition, unlike in cosmetic use, the polymeric microbeads must be thermally stable to survive the extrusion process. Therefore, microbeads are subject to a cross-linking process when they are produced. The process involves a chemical reaction that converts the polymer from a thermoplastic to a thermoset. The microbeads are subsequently stable to heat when compounded into the host polymer and thereby maintain the original spherical shape.

It is important to mention that converters of PMMA and PC articles such as producers of profiles, lenses, covers, and sheets cannot introduce the LD additive directly into their process. The LD additives have a very low bulk density, and therefore specialized equipment is needed in order to dose them into the machines. Also, dedicated processing tools are required to disperse the additive in the polymer uniformly. Therefore, LED cover or optic manufacturers must acquire LD additive that is already compounded into the host polymer, as produced by compounding companies that specialize in this unique segment.

LD additive cost

Of course, cost is also an important parameter when selecting an LD system. On the one hand, LD additives with higher purity, improved thermal stability, and narrow particle size distribution will cost more. On the other hand, such additives will perform much better in terms of light diffusing quality and luminance level. The cost impact of the LD additive on the PMMA or PC cover part is limited, as its concentration in the carrier is very small: 0.3%-1.0%. Therefore, even if there is a $20/kg cost difference between two types of LD additives, the final difference can be acceptable. In an average LED cover, the weight is 0.5 kg, resulting in only $0.10 difference per unit.

FIG. 6. The microscope picture of pure microbeads shows an average particle size of 4 μm.

Moreover, experiments indicate that the optimal level of LD additive in a polymeric cover depends on both the LD additive concentration and the cover part thickness. The concentration, to a good approximation, is inversely proportional to the thickness. Thus, for example, if a part of 1-mm thickness requires 0.6% of LD additive. Then for a part of 2-mm thickness, approximately only 0.3% is needed to get the same extent of light diffusion.

Compounded LD additive in PMMA or in PC is offered by the compounding companies in two forms:

- Ready-made compound - with the main advantage that the LD converters can use the compound as is. Use as is means direct dosage into the injection molding or extrusion line without any additional actions.

- Masterbatch (MB) form - in this case, the converters need to blend the masterbatch with PMMA or PC at a certain dosing level. They can pre-mix the MB with the host polymer prior to introduction into the machine or perform the mix in-line by using dosing systems.

Ready compound is easy to process without any dispersion problems; however, it is much more expensive in comparison to the MB option. Therefore, converters that deal with large quantities should consider using MB rather than ready-made compound. Moreover, use of MB provides flexibility and control for the converter by allowing them to increase or reduce the LD additive level in the product according the product thickness and customer specification.

Summary

LED lighting systems are everywhere today - in private houses, shopping centers, train stations, factories, businesses, street lighting, and more. Attention should be paid to the performance of the light diffusion system. In particular, questions should include: Is the light diffusion uniform in the product? Can the light source shape be seen? Is it a high luminance system?

High-quality materials for these applications depend on the choice of light diffuser additive systems, so that they contribute to maximum energy utilization of the LED device. As we have discussed, on one hand, optimal systems allow a high level of light to be transmitted and at the same time, they provide for high diffusion of the transmitted light.

Government regulations and consumer preference for more environmentally-conscious, energy-efficient products have caused manufacturers to develop solutions for the marketplace that offer new levels of energy efficiency, based on LED technology. This trend will lead to a continuous increase in the LED technology market share among other light technologies. As a result, there will continue to be more demand for light diffusion systems with high-quality performance.

ACKNOWLEDGMENT

The author gratefully acknowledges the assistance and helpful comments of Moira M. Nir, PhD, of Tosaf Compounds R&D Department in preparing this article.

GABI BAR is the global polycarbonate manager for Tosaf Compounds Ltd. (tosaf.com).